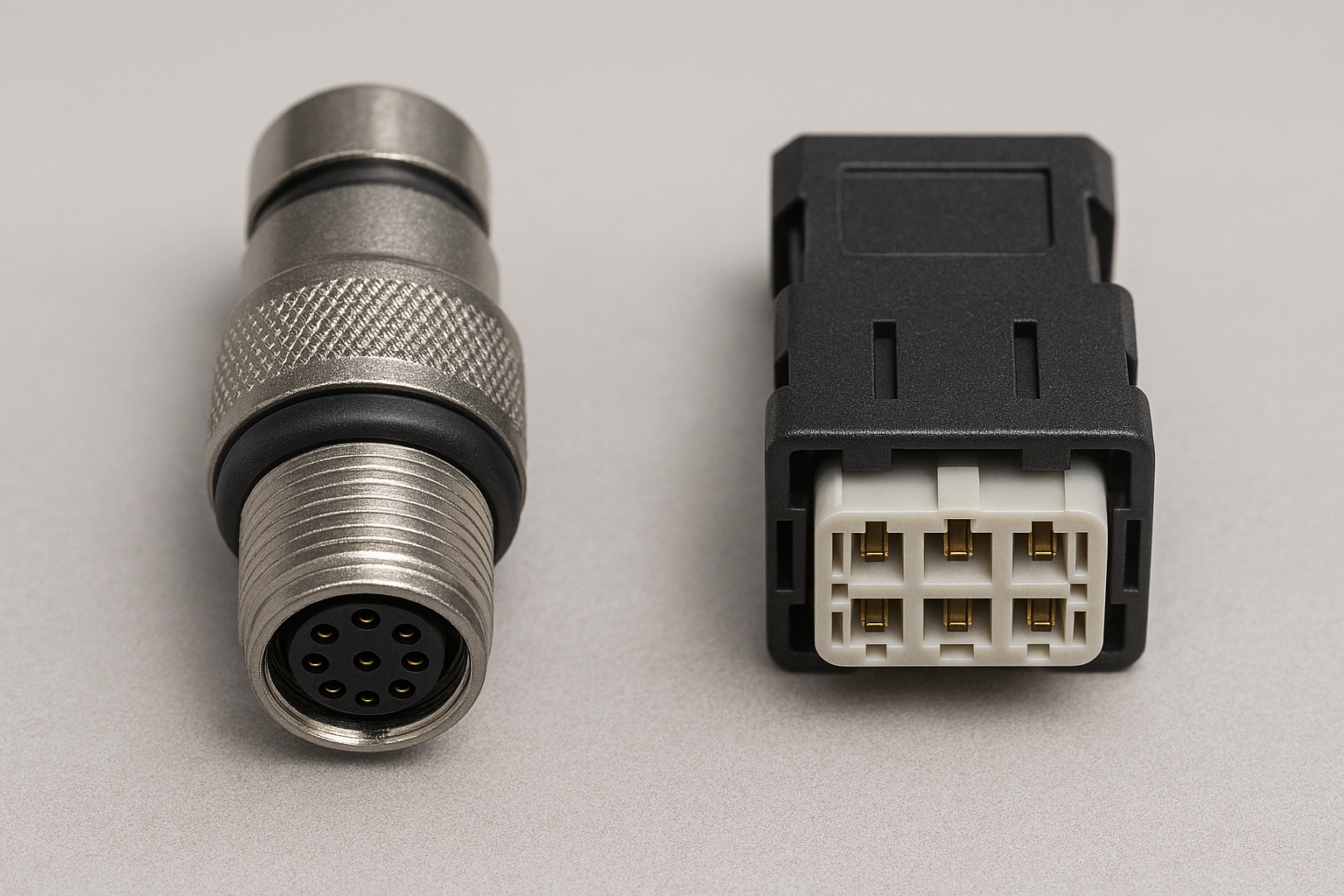

Circular Connectors vs Rectangular Connectors: Which is More Suitable for Industrial Applications?

What Are Rectangular Connectors?

Advantages:

Key Differences: Circular vs Rectangular Connectors

| Feature | Circular (e.g. Connoder M16) | Rectangular |

| Environmental Sealing | Excellent sealing; easy to achieve IP67/68 | More complex to seal; multiple flat surfaces |

| Durability | Superior against vibration, shock, and outdoor exposure | Robust but may require reinforcement |

| Contact Density | Moderate; limited by diameter | High; supports modular inserts |

Installation | Simple to mate/unmate in confined spaces | Better for structured cabinet integration |

Best Use Case | Harsh environments, field equipment, robotics, renewable energy | Control cabinets, machinery, high-density wiring |

Which Is More Suitable for Industrial Applications?

Choose Circular Connectors (like M16) when:

Choose Rectangular Connectors when:

Why Connoder Recommends M16 Circular Connectors for Harsh Industrial Use