M9 Circular Connector

M9 Circular Connector

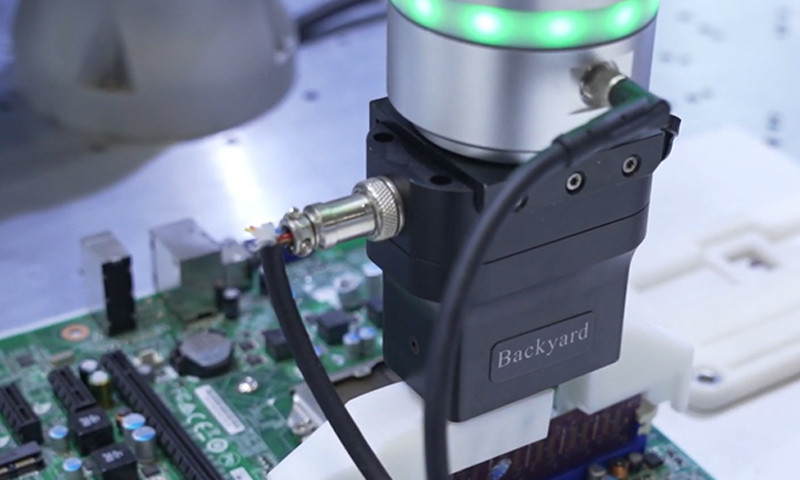

Engineered for high-density signal and power integration in ultra-compact industrial systems, M9 circular connector delivers superior electrical performance and mechanical resilience where space is at a premium.

- High-Density Miniaturization: With a 9 mm thread diameter, it enables greater pin density than M8 while maintaining robust mechanical integrity—ideal for next-gen compact devices.

- Precision Threaded Coupling: Metal-to-metal mating with full 360° coupling nut ensures vibration resistance and stable EMI shielding in dynamic applications.

- IP67 Protection: Fully sealed against dust, high-pressure water jets, and aggressive cleaning agents—validated for washdown-intensive environments.

- Hybrid Signal & Power Options: Available in 2P, 3P, 4P, 5P, 6P and 8P configurations supporting mixed signal, data, and power transmission in a single interface.

- Full 360° EMI Shielding: All-metal housing and shielded contact carriers ensure signal integrity up to 500 MHz in high-noise industrial settings.

- Drop-in Compatibility: Designed as functional equivalents to leading-brand high-density connectors—enabling seamless integration without system re-engineering.

- IEC-Aligned Reliability: Built to extended IEC 61076-2 design principles with >10 million mating cycles and -40°C to +85°C operational range.

The M9 connector combines miniaturization with industrial-grade durability. Its gold-plated contacts (≥0.75 µm), overmolded strain relief, and corrosion-resistant brass housing ensure stable performance in robotics, mobile machinery, and embedded sensing—even under continuous flexing or thermal cycling.

Typical Applications

Collaborative robot (cobot) joints, miniature vision & LiDAR sensors, AGV navigation modules, servo motor feedback systems, medical automation equipment, and compact IIoT edge devices.

At Connoder, we provide standard M9 connectors as well as custom-configured solutions—including pre-assembled cable sets with PUR or PVC jacketing—to meet your exact signal, power, and environmental requirements.

M9 Circular Connector Types

M9 Circular Connector Panel Mount

M9 Circular Connector Assembled

M9 Pre-Molded Cable Assemb

- Circular Connectors

- Type

- M5 Circular Connector

- M8 Circular Connector

- M9 Circular Connector

- M12 Circular Connector

- M14 Circular Connector

- M16 Circular Connector

- 7/8 " Circular Connector

- Shape

- Straight

- Right Angle

- Gender

- Female

- Male

- Number of cores

- 2 Pin

- 3 Pin

- 4 Pin

- 5 Pin

- 6 Pin

- 7 Pin

- 8 Pin

- 9 Pin

- 12 Pin

- 14 Pin

- 16 Pin

- 17 Pin

- 19 Pin

- 24 Pin

- 1+PE

- 2+PE

- 3+PE

- 4+PE

- 5+PE

- 6+PE

- 3+5 Pin

- 3+7 Pin

- 2+FE

- 3+FE

- 4+FE

- Foolproof type

- A

- B

- C

- D

- K

- L

- M

- P

- S

- T

- X

- General

- Protection level

- IP66

- IP67

- IP68

- Wiring method

- Solder type

- PCB type

- Screw type

- SMD type

- Installation type

- Rear Fastened

- Front Fastened

- Square Flange Socket

- Sockets

- SMD Sockets

- Plastic Assembled

- Metal Assembled

- Curved Metal Assembly

- Ordinary Overmolded Type

- Overmolded Type

- Shielding type

- Shielded

- Unshielded

- Yes/No Optional

- Housing material

- Metal

- Plastic

- Metal + Plastic

- Rated voltage

- 30V

- 48V

- 50V

- 60V

- 63V

- 125V

- 250V

- 630V

- 300V

- 800V

- Rated current

- 0.5A

- 1A

- 1.5A

- 2A

- 3A

- 4A

- 5A

- 6A

- 7A

- 8A

- 9A

- 12A

- 13A

- 16A

- Insulation resistance

- 5mΩ

- 8mΩ

M9 Circular Connector

M9 Circular Connector

Downloads on The Topic of Circular Connectors

Applications of Circular Connectors

M9 Circular Connector Technical Guide

Comparison of Pin Numbers and Coding Differences of M9 Circular Connectors

| Pins | 2 | 3 | 4 | 5 |

| Male |  |

|

|

|

| 6 | 7 | 8 | ||

|

|

|

||

| Pins | 2 | 3 | 4 | 5 |

| Femle |  |

|

|

|

| 6 | 7 | 8 | ||

|

|

|

Pin Configuration and Electrical Parameters of M9 Circular Connectors

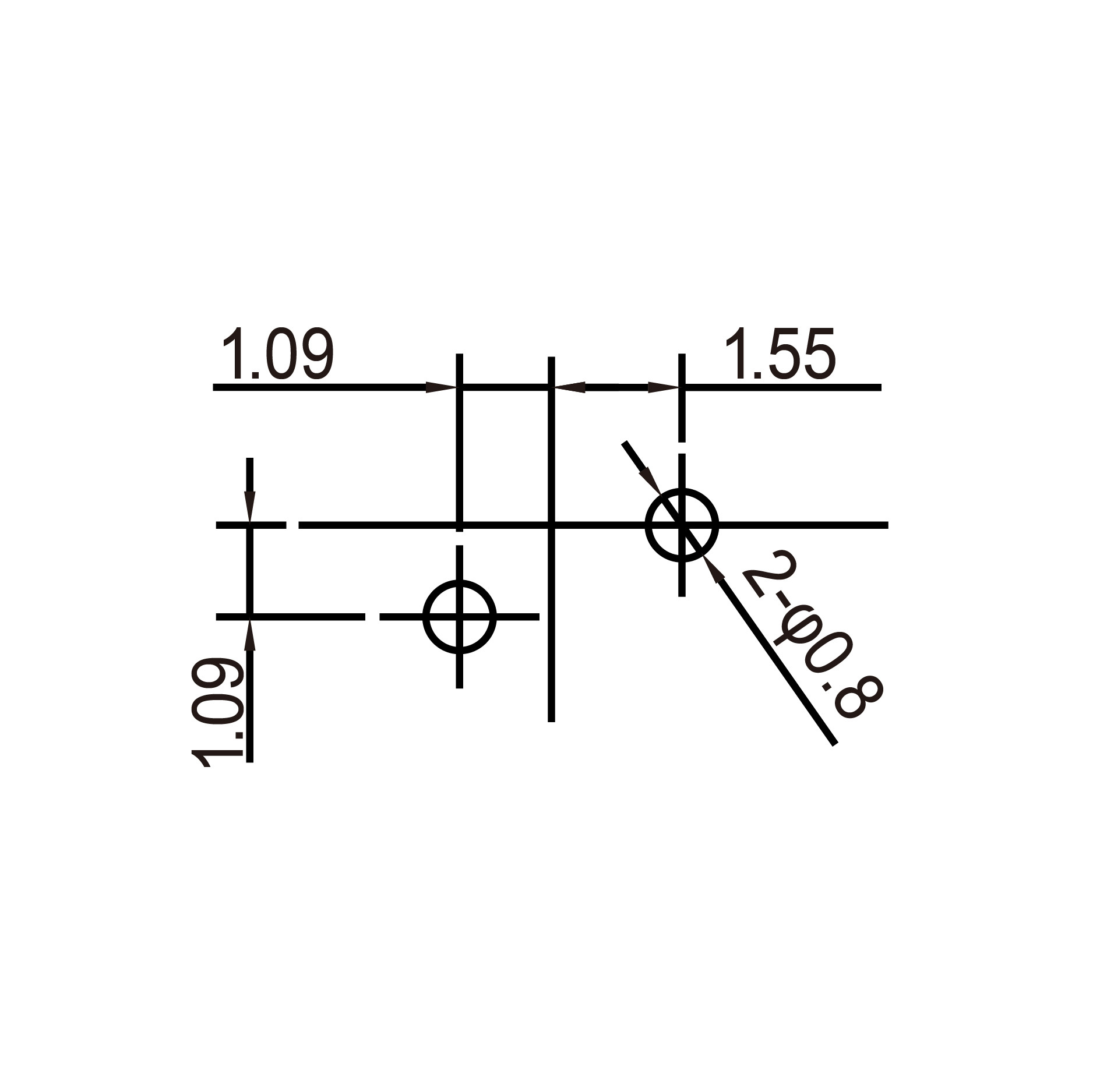

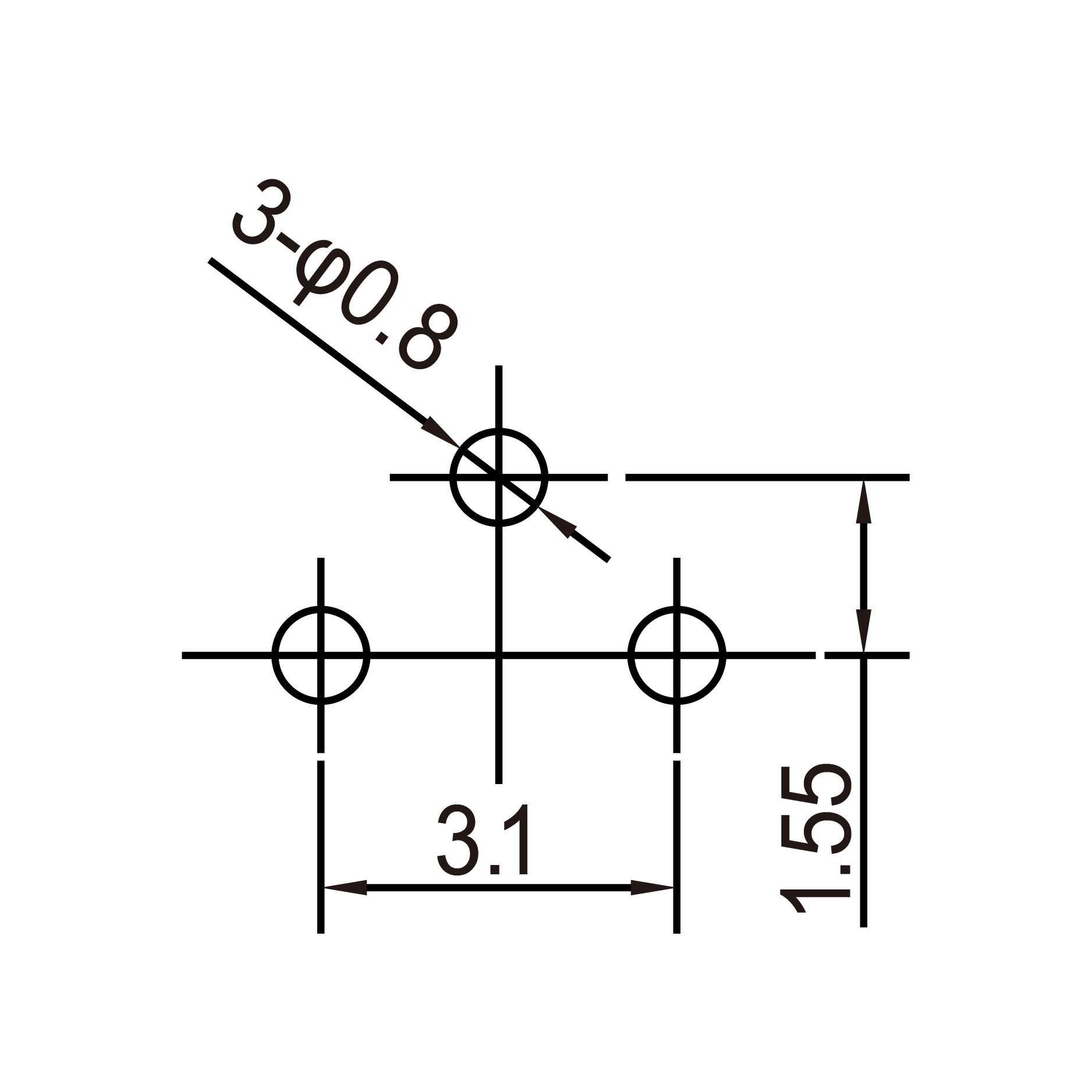

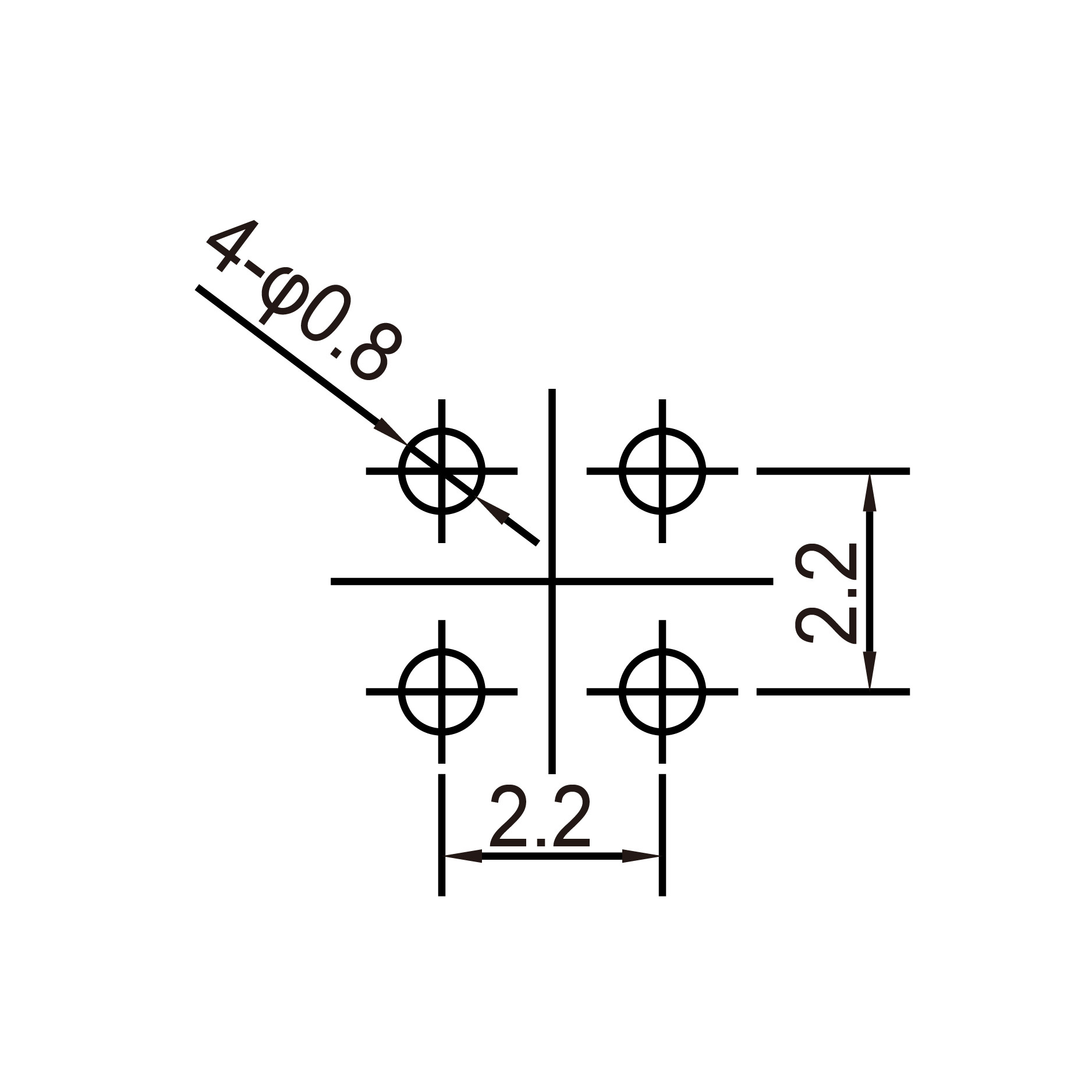

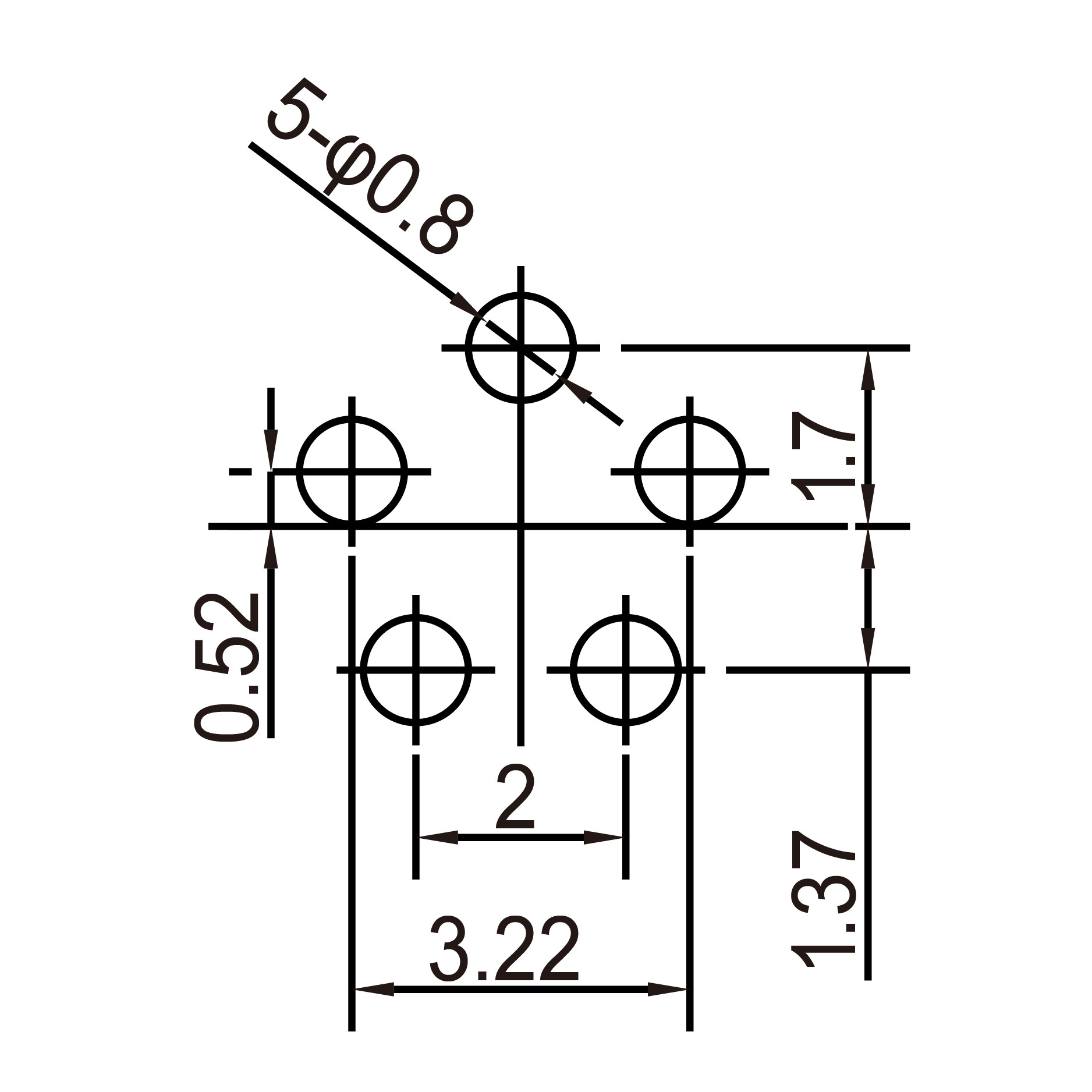

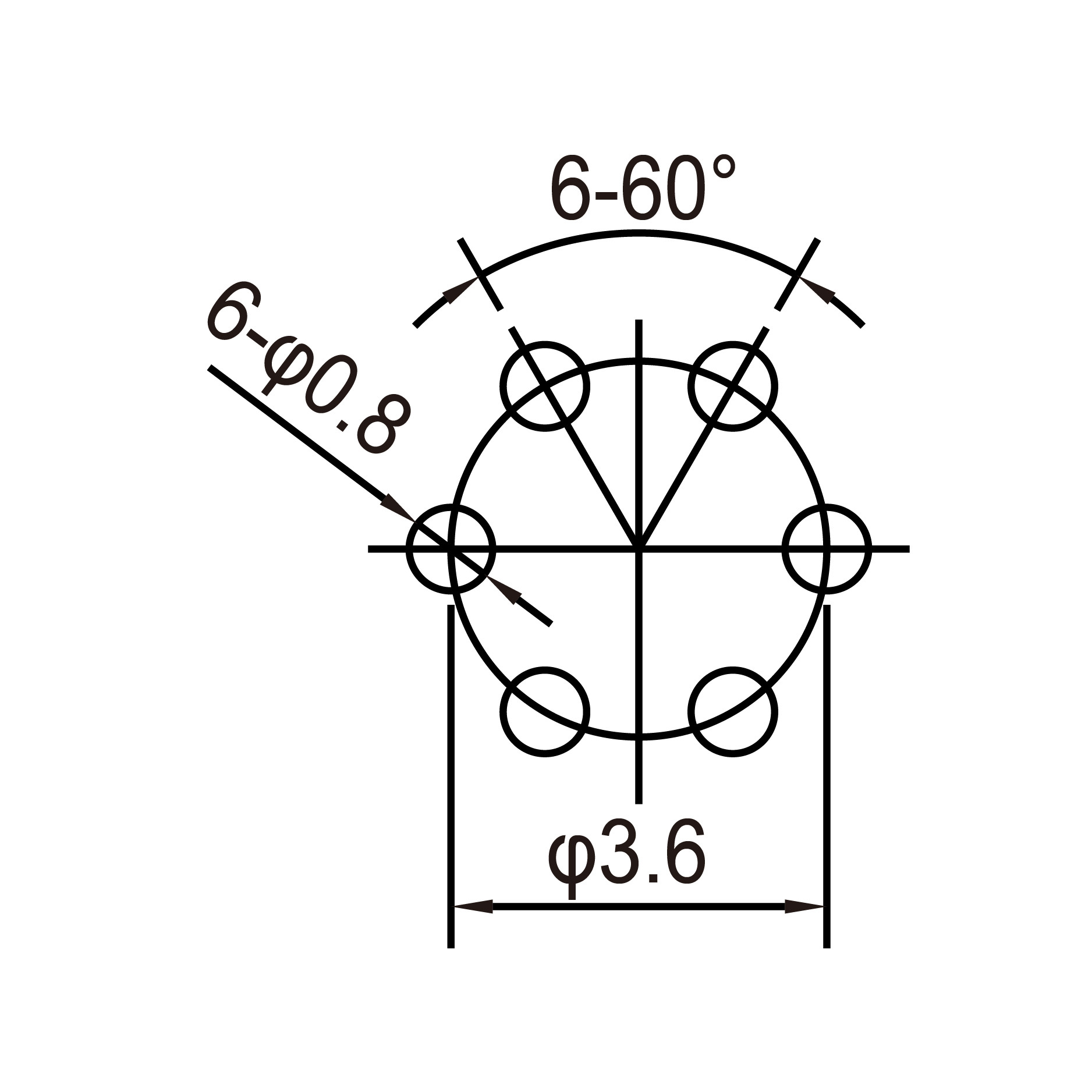

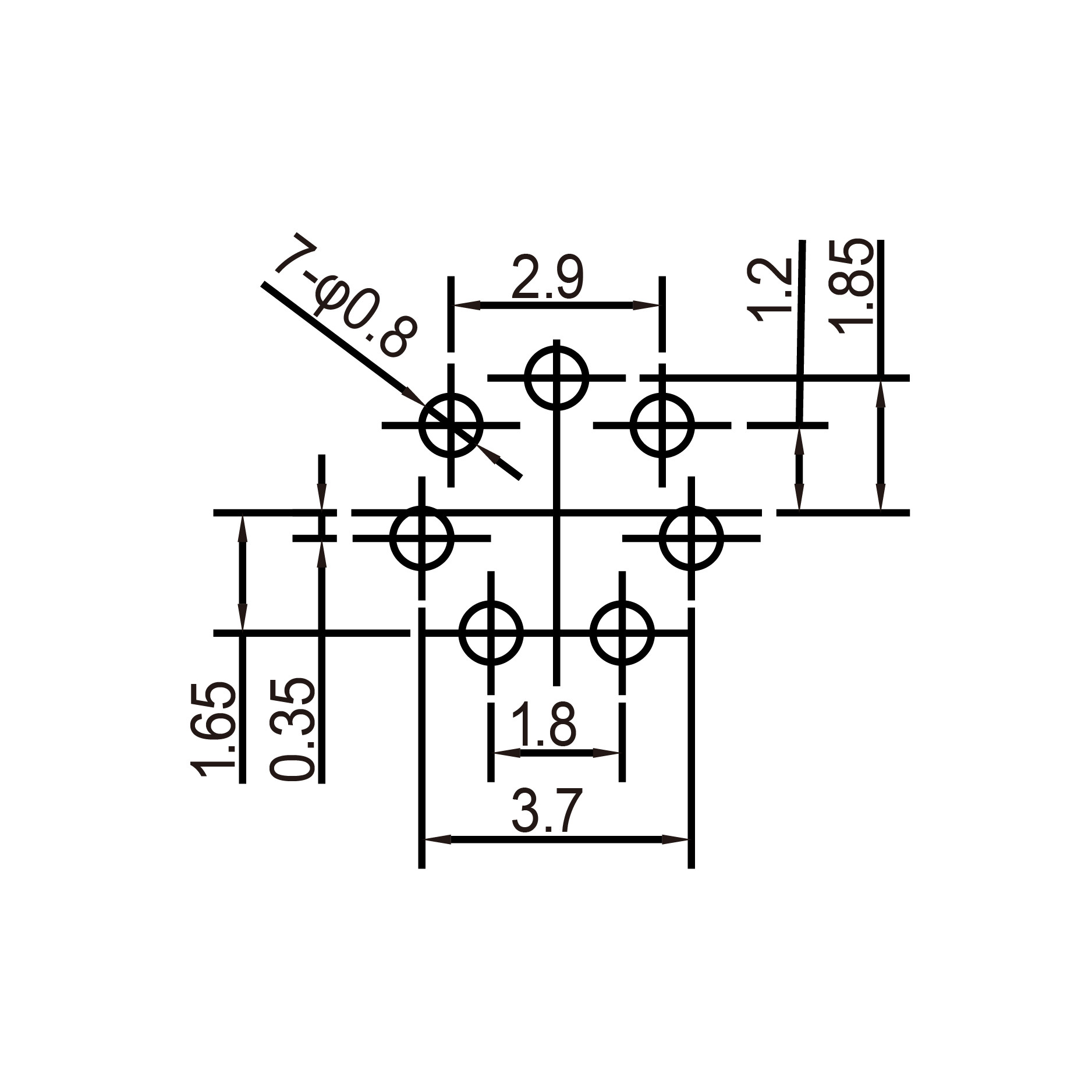

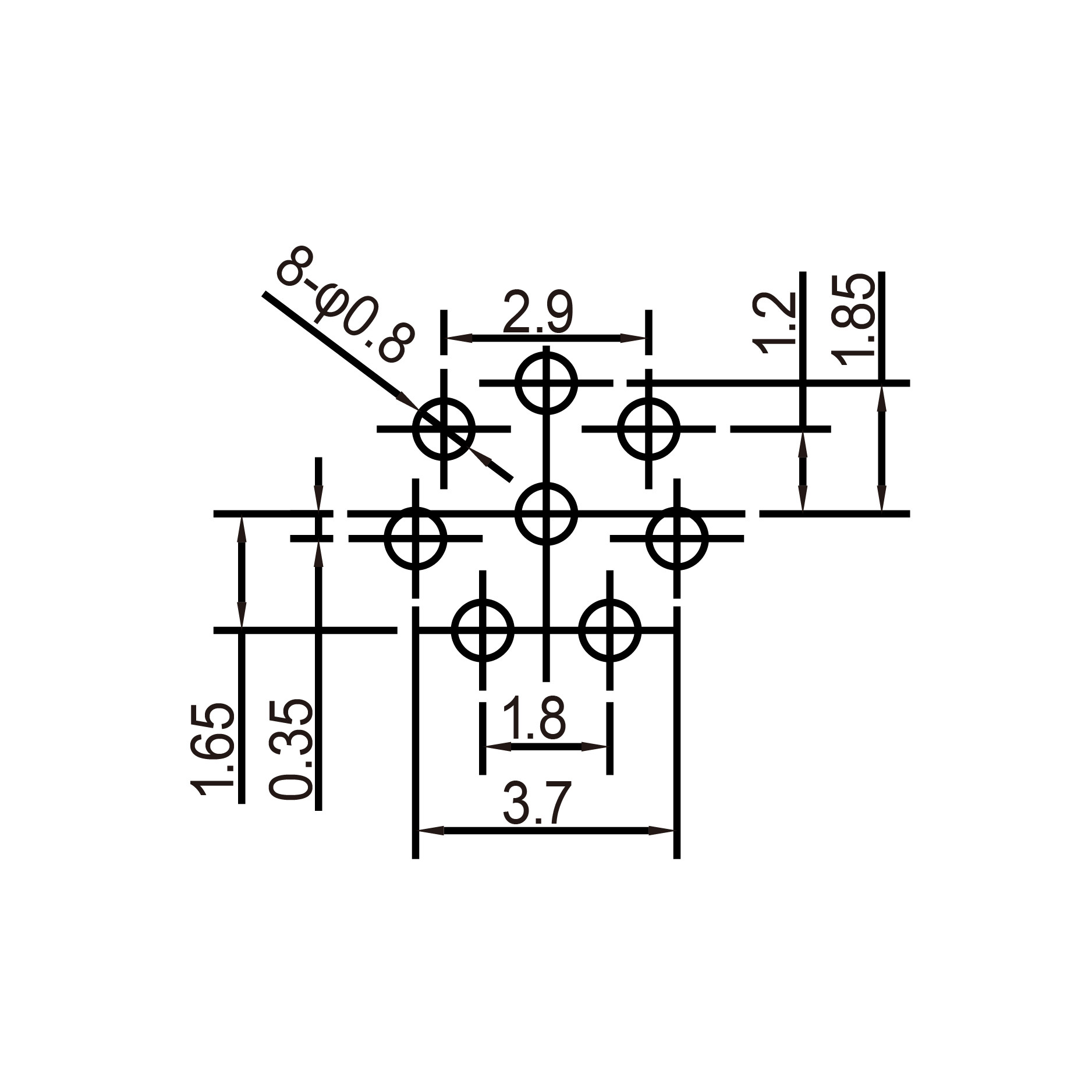

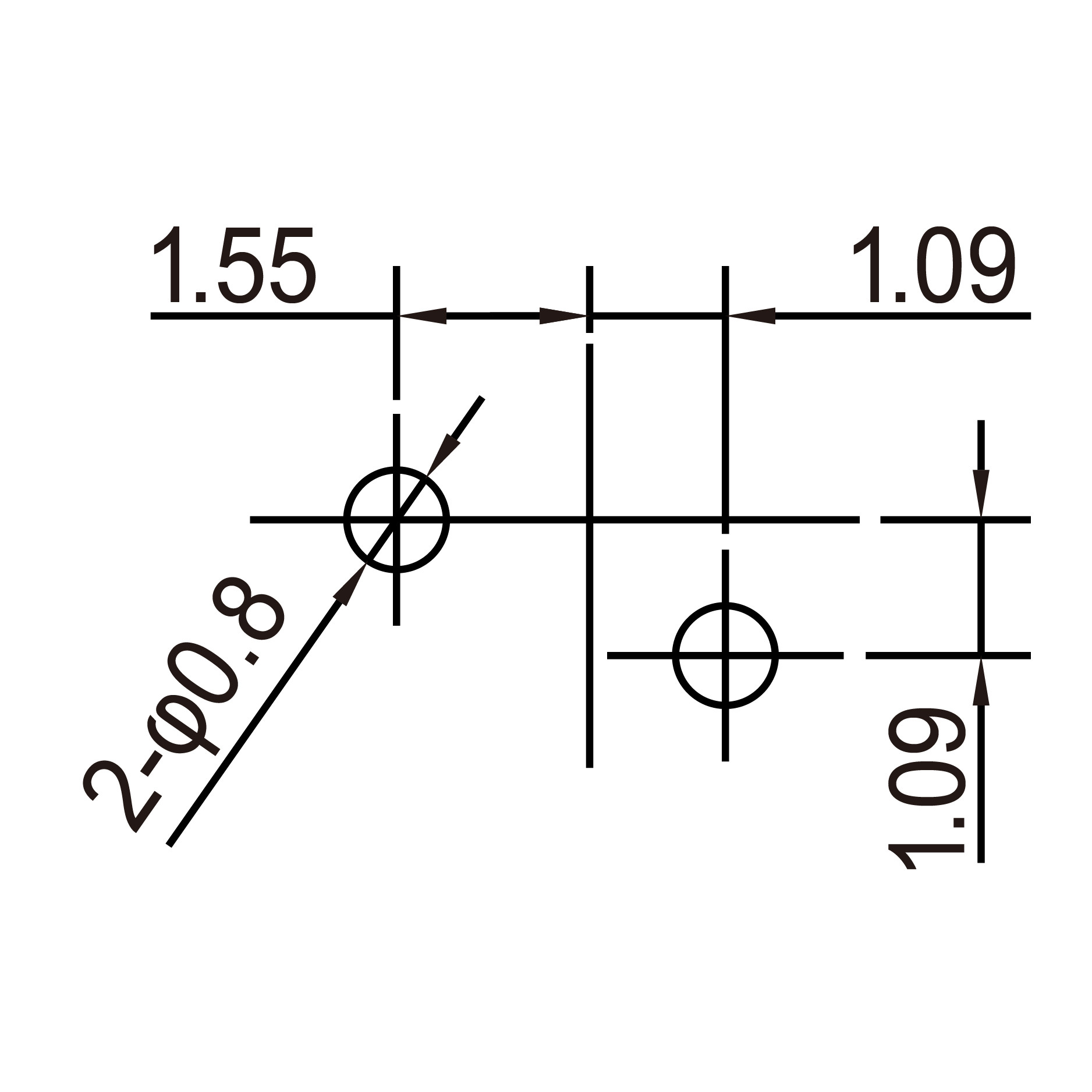

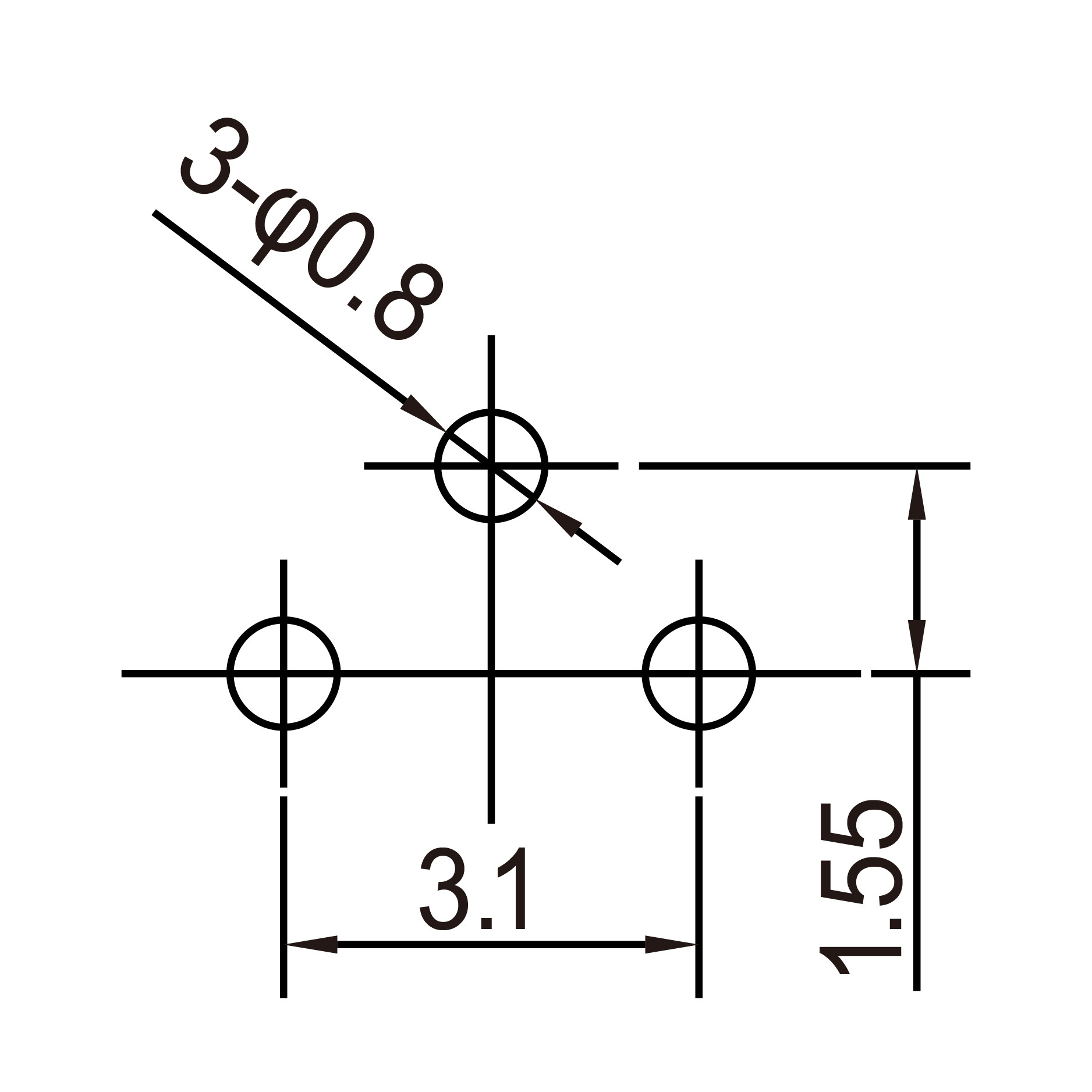

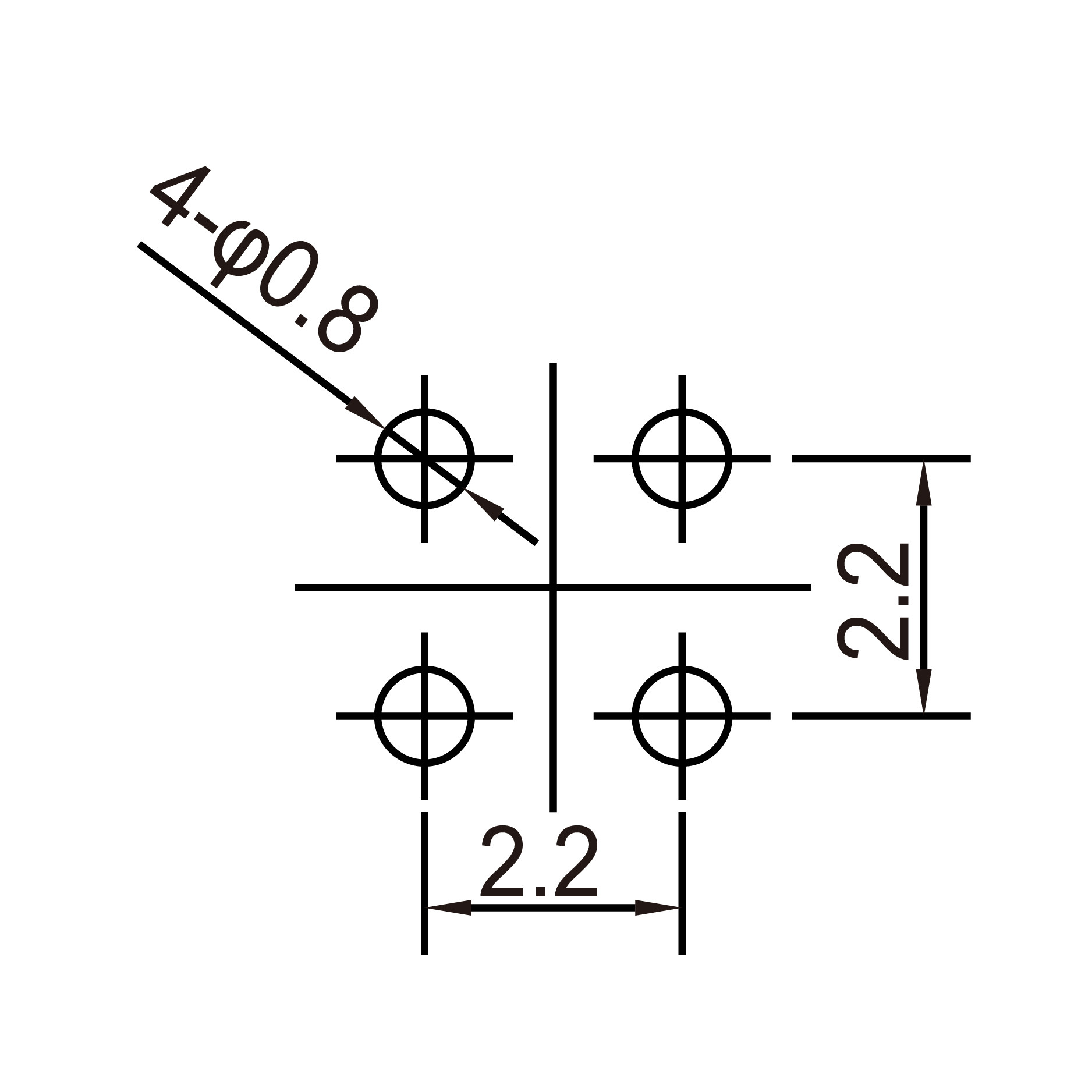

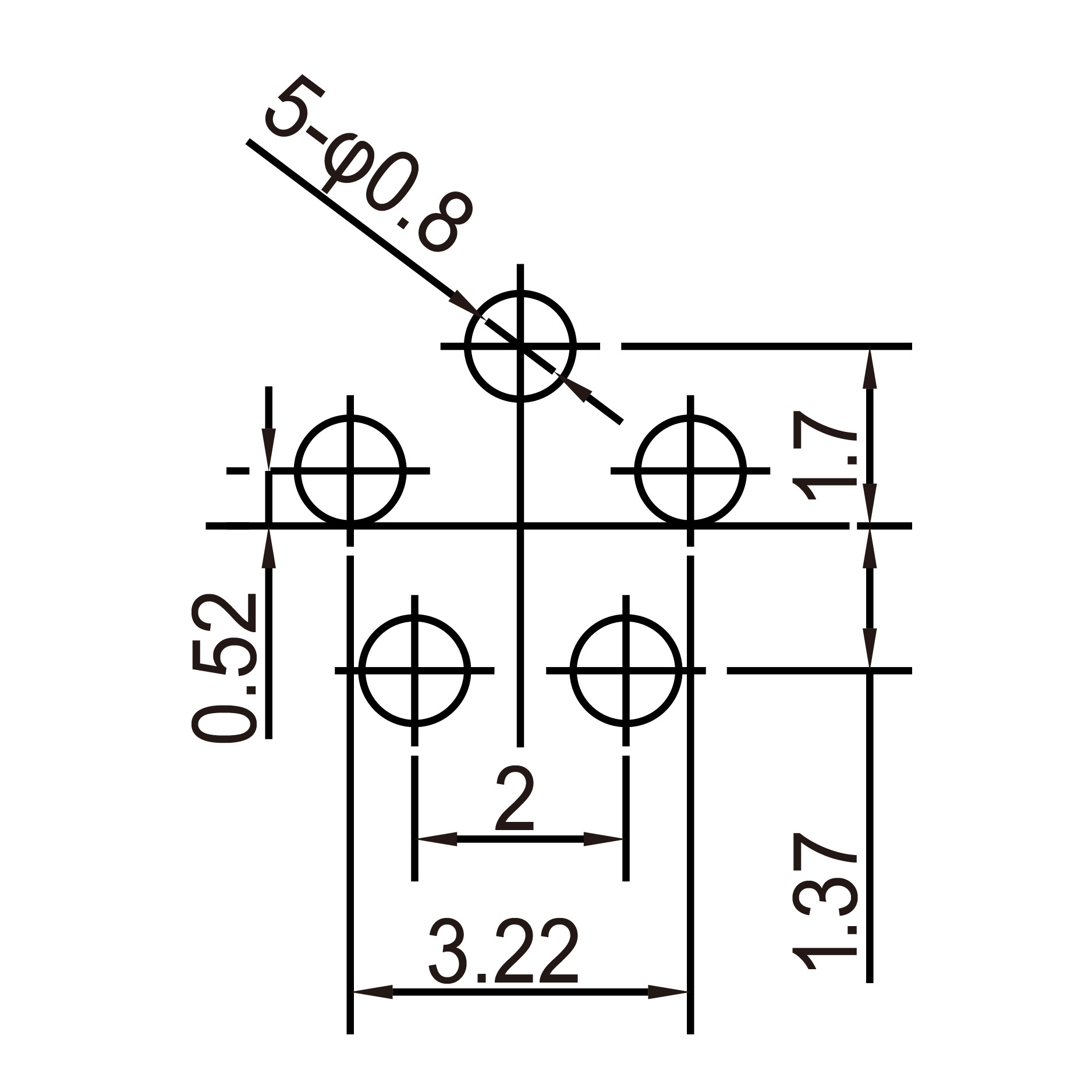

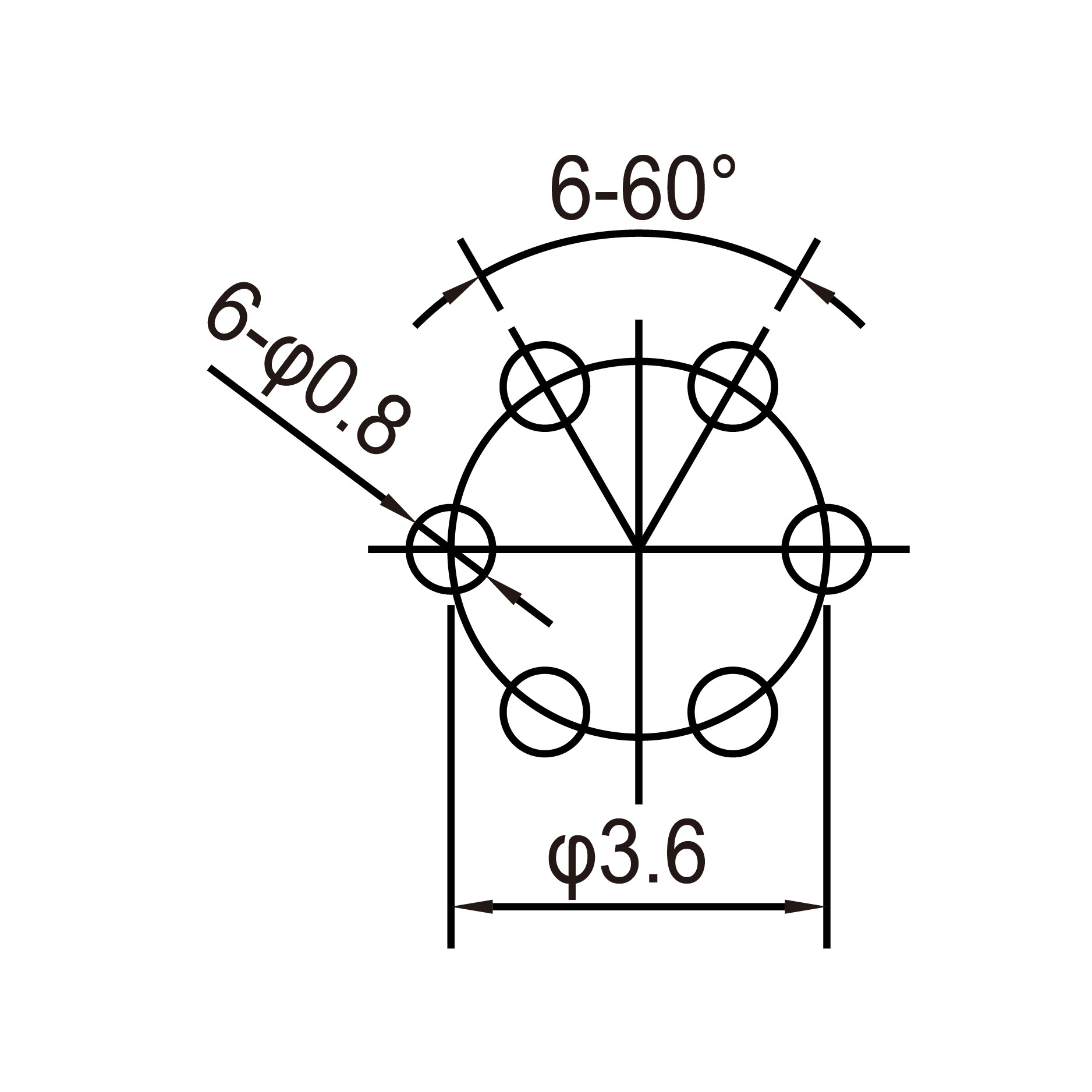

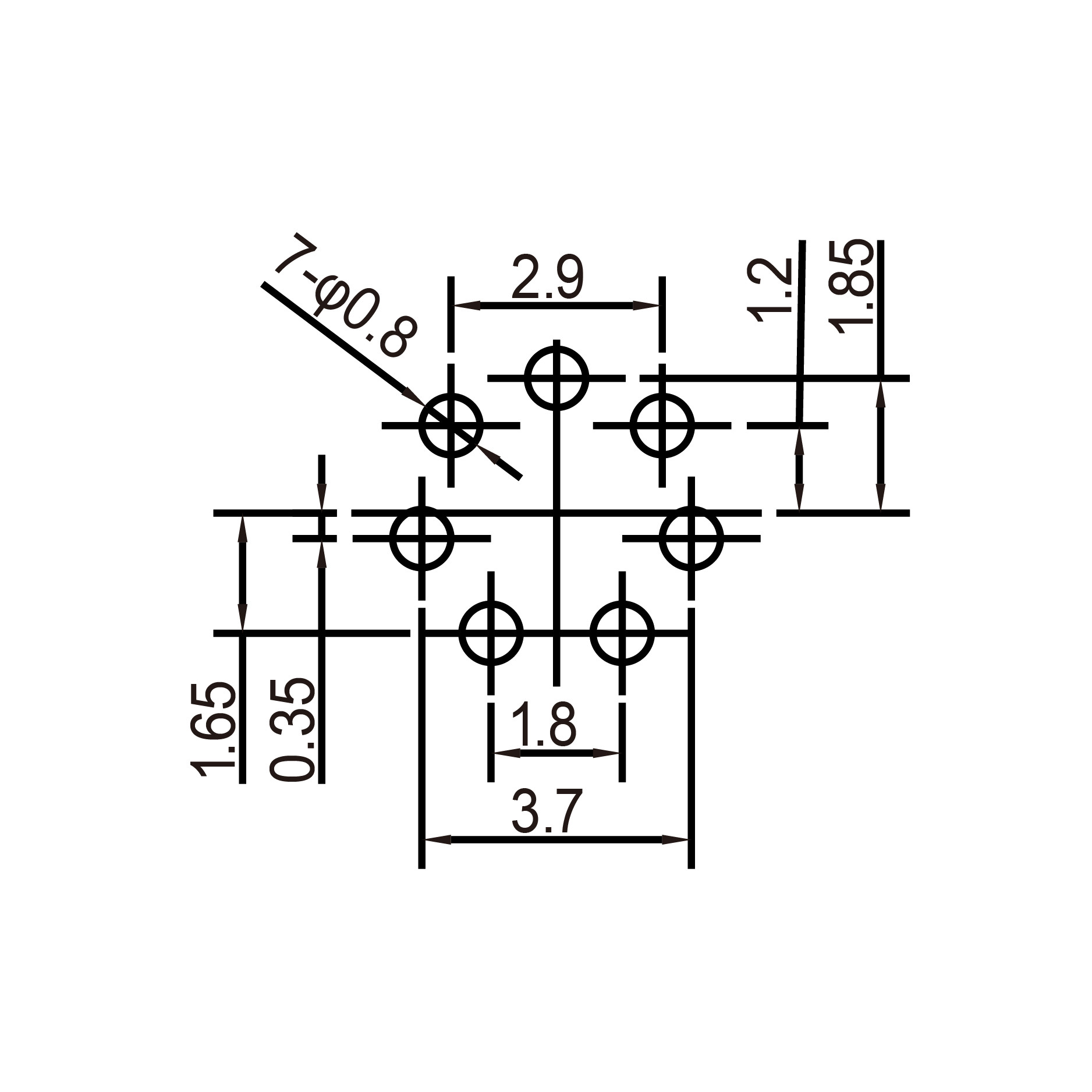

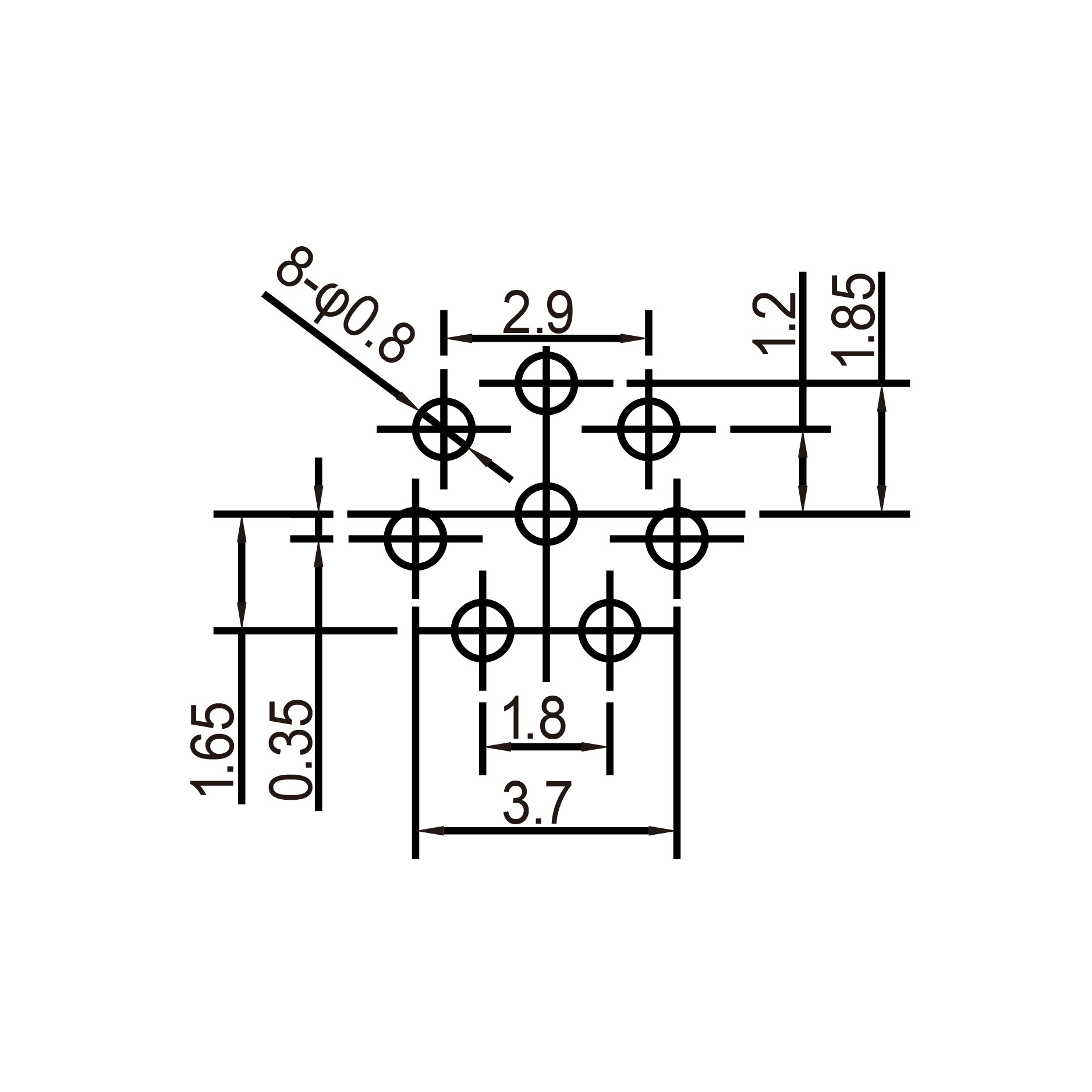

M9 PCB Pins Arrangement

Different Installation Methods of Circular Connectors

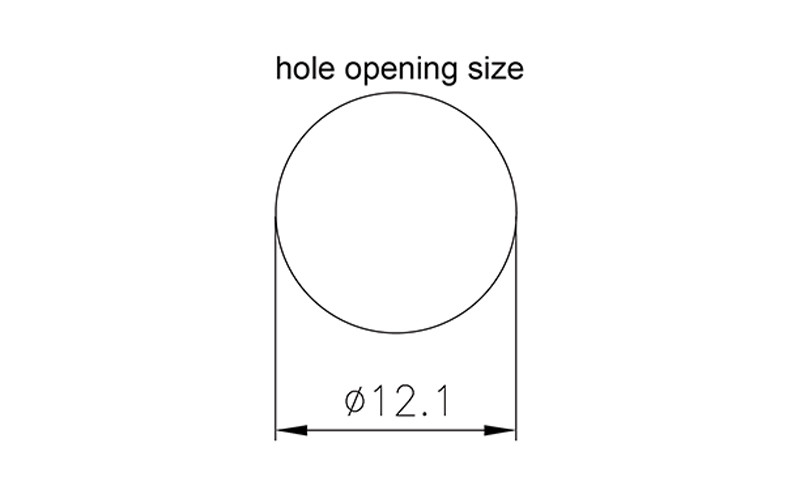

Different Opening Sizes of Circular Connectors

Different Wiring Methods for M9 Circular Connectors

Wiring Definition of M9 Circular Connectors

| Pins | 2 Pin Core Color | Pins | 6 Pin Core Color | ||

| 1 | BN | 1 | BN | ||

| 2 | BU | 2 | WH | ||

| 3 | BU | ||||

| Pins | 3 Pin Core Color | 4 | BK | ||

| 1 | BN | 5 | GY | ||

| 2 | BU | 6 | PK | ||

| 3 | BK | ||||

| Pins | 7 Pin Core Color | ||||

| Pins | 4 Pin Core Color | 1 | WH | ||

| 1 | BN | 2 | BN | ||

| 2 | WH | 3 | GN | ||

| 3 | BU | 4 | YE | ||

| 4 | BK | 5 | GY | ||

| - | 6 | PK | |||

| Pins | 5 Pin Core Color | 7 | BU | ||

| 1 | BN | ||||

| 2 | WH | Pins | 8 Pin Core Color | ||

| 3 | BU | 1 | WH | ||

| 4 | BK | 2 | BN | ||

| 5 | GY | 3 | GN | ||

| 4 | YE | ||||

| 5 | GY | ||||

| 6 | PK | ||||

| 7 | BU | ||||

| 8 | RD | ||||

Global Compatibility and Mil-Spec Solutions

Explore our catalog of high-reliability connectors, including our complete M-series lineup, compatible with leading brands such as:

www.connoder.com

Why Choose Connoder Circular Connectors?

Quality Assurance

Customization

Global Support

Innovation

Certification

Sales Network

Why Choose Connoder Circular Connectors?

Please Send Your Message To Us

- Name

- Phone

- *Title

- *Content