When faced with a multitude of options, how do you pick the best circular connector cable for your project's needs? Here are a few suggestions that may help:

Define the functional requirements: First of all, it is necessary to know clearly what type of data/signal transmission or power supply the cable will be used for, which will directly determine the selection of the subsequent parameters.

Evaluate the operating environment: Carefully analyze the characteristics of the potential operating environment, such as temperature range, humidity level, presence of corrosive substances, etc., in order to determine whether additional protective measures are required.

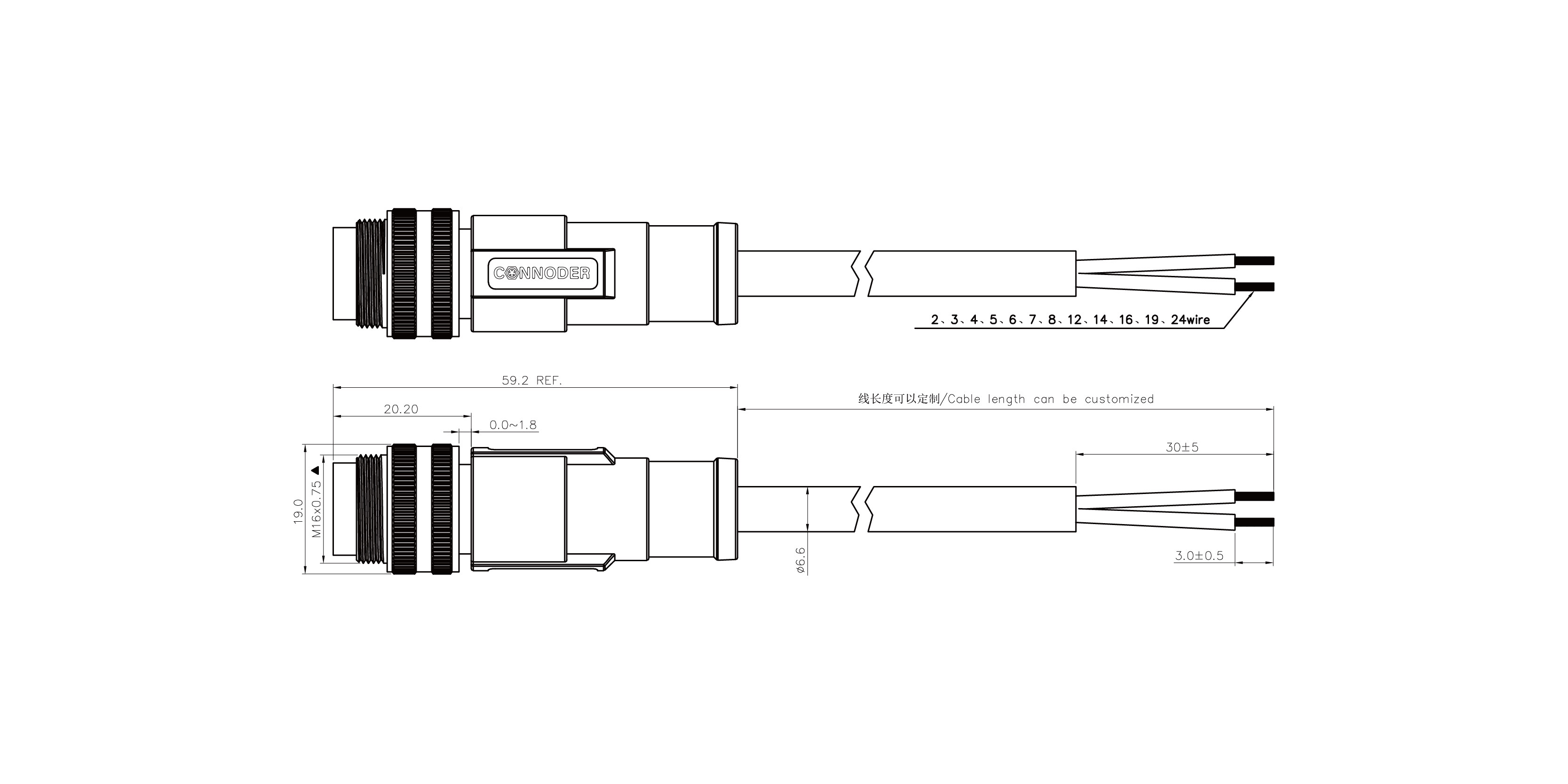

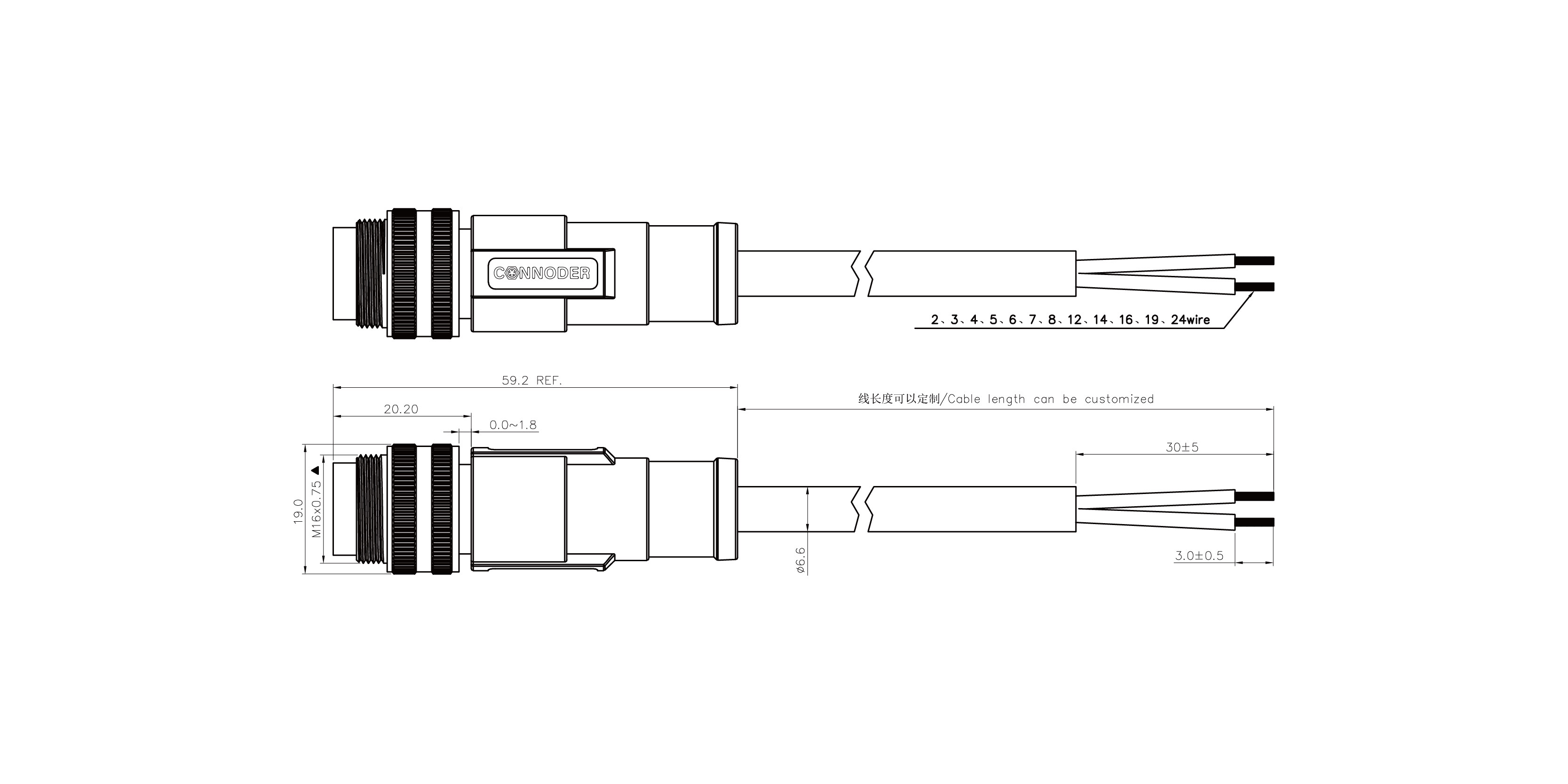

Check physical dimensional constraints: Considering the limitations of the installation space, it is sometimes necessary to pay special attention to the overall dimensional requirements of the connector.

Review the electrical parameters: accurately check the maximum voltage and current values required to be supported, as well as other relevant electrical indicators, to ensure that the selected model can fully meet the actual operational requirements.

Confirm interface standards compatibility: Ensure that the selected circular connector complies with established industry standards and allows for seamless interoperability with other components.

Consider long-term reliability: In addition to initial performance, focus on durability and consistency over the life of the product.