Manufacturing Process Of Wire Harnesses

Executive Summary

1. Introduction to Wire Harness Manufacturing

2. Key Phases in the Manufacturing Process Of Wire Harnesses

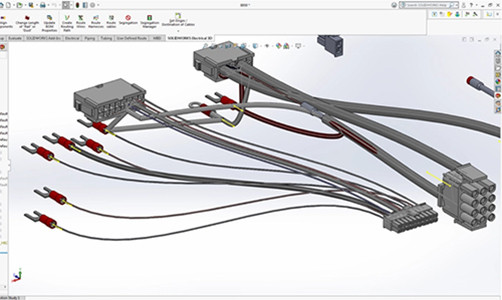

2.1. Design & Engineering

2.2. Material Selection

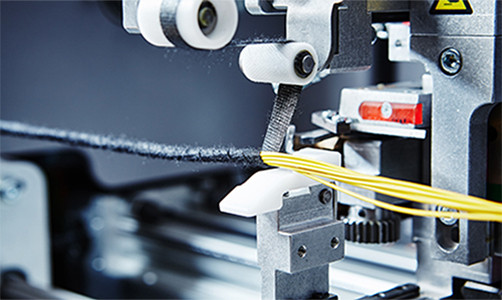

2.3. Cutting & Stripping

2.4. Crimping & Soldering

2.5. Assembly & Routing

2.6. Testing & Quality Assurance

3. Why B2B Customers Choose Us

3.1. End‑to‑End Supply‑Chain Integration

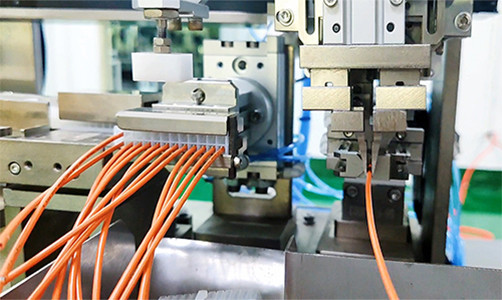

3.2. Advanced Automation & Capacity

3.3. Certified Quality & Compliance

3.4. Customization & Agile Engineering

4. Customer Pain Points & Our Solutions

| Pain Point | Our Solution |

| Long lead times | Flexible shift schedules and buffer inventory enable 2–4 week standard lead. |

Quality inconsistency | 100% in‑line testing and SPC data analytics eliminate batch variation. |

Hidden costs & overruns | Transparent quoting system and lean manufacturing drive cost predictability. |

Lack of technical collaboration | Dedicated application engineers provide DFMEA and on‑site support. |

Complex compliance requirements | We maintain full certification library and advise on evolving regulations. |