What Are Circular and Rectangular Connectors?

What Are Circular and Rectangular Connectors?

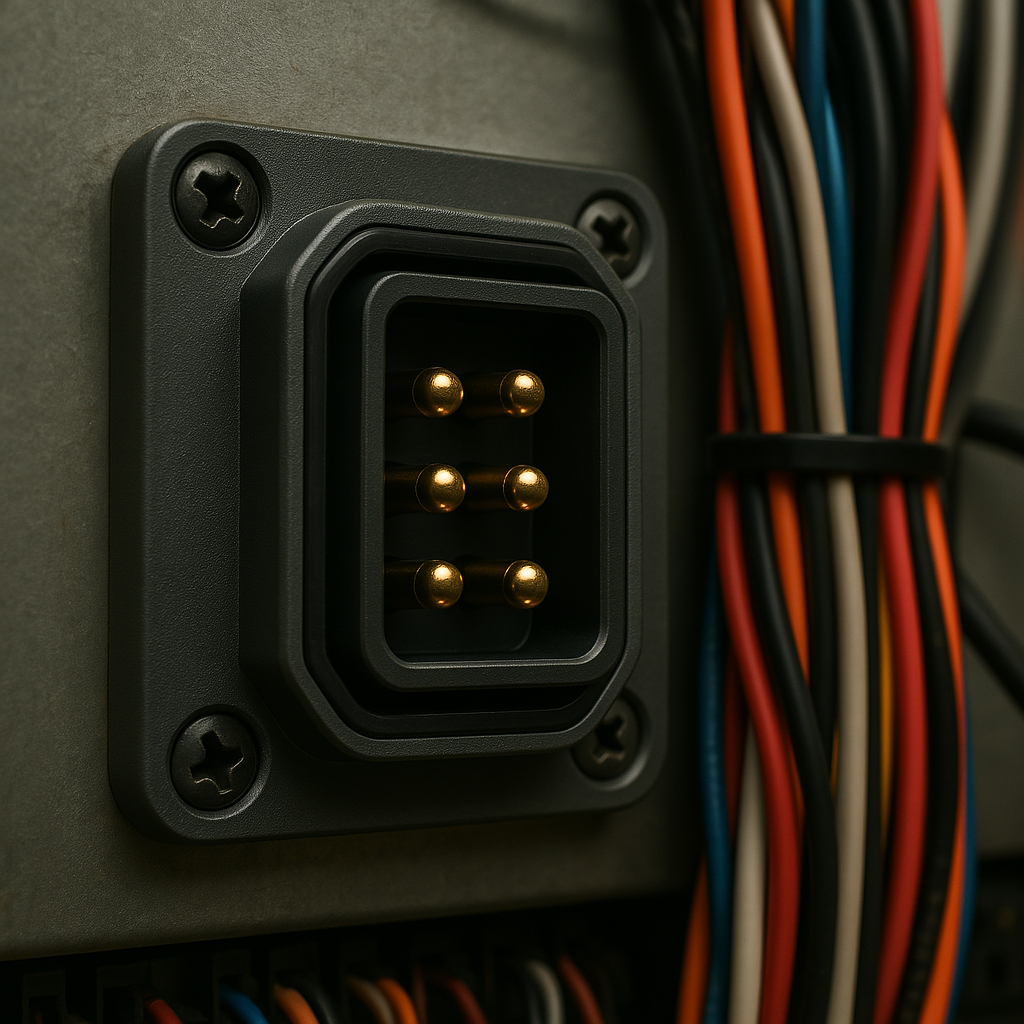

Circular connectors are cylindrical with concentric pin layouts, providing superior sealing and vibration resistance. Rectangular connectors use a box-shaped layout, maximizing pin density and space efficiency.

Key Differences at a Glance

| Feature | Circular Connector | Rectangular Connector |

|---|---|---|

| Shape | Cylindrical | Rectangular / Flat |

| Contact Layout | Radial | Grid-based |

| Environmental Protection | Excellent (IP67+) | High (IP67) |

| Installation | Threaded, bayonet | Snap-lock, flange-mounted |

When Should You Use Circular Connectors?

Circular connectors are best for rugged environments such as aerospace, robotics, and outdoor installations. They offer excellent vibration resistance and are easy to lock in place.

When Rectangular Connectors Are the Better Choice

Rectangular connectors are ideal for compact panels and mixed-signal applications. Their high contact density and modularity make them perfect for complex industrial wiring.

Application Comparison Table

- Outdoor, rugged use: Circular

- Compact control panels: Rectangular

- Hybrid signal/power: Rectangular

- Quick connection: Circular

Durability & Environment

Both connector types are available in IP67 variants, but circular connectors offer stronger mechanical resistance. Rectangular types offer installation efficiency and high pin density.

Why Choose Connoder?

- IP67 waterproof connectors for harsh environments

- Compact M16 options – round and square

- Custom solutions and technical support

- Fast response and global shipping

Contact Connoder now for consultation »

Conclusion

Circular connectors are best for rugged durability and environmental resistance. Rectangular connectors shine in space efficiency and modular flexibility. With Connoder, you can confidently source high-performance connectors for every industrial scenario.