Why M12 Connector Troubleshooting Matters

Why M12 Connector Troubleshooting Matters

In industries where uptime and signal integrity are critical, M12 circular connectors are widely used to connect sensors, actuators, and control units. But even the most robust components can degrade over time due to environmental factors, improper installation, or mechanical stress.

At Connoder, we help you solve connector failures efficiently. With years of experience in industrial-grade connectivity solutions, our M12 products are designed for high durability and easy maintenance.

👉 Learn more about our company and products

Tools You’ll Need

- Multimeter (for continuity and resistance testing)

- Isopropyl alcohol and lint-free cloth

- Torque wrench (optional but ideal)

- Replacement M12 connectors or cables

Step 1: Perform a Visual Inspection

Start with the simplest but most important step:

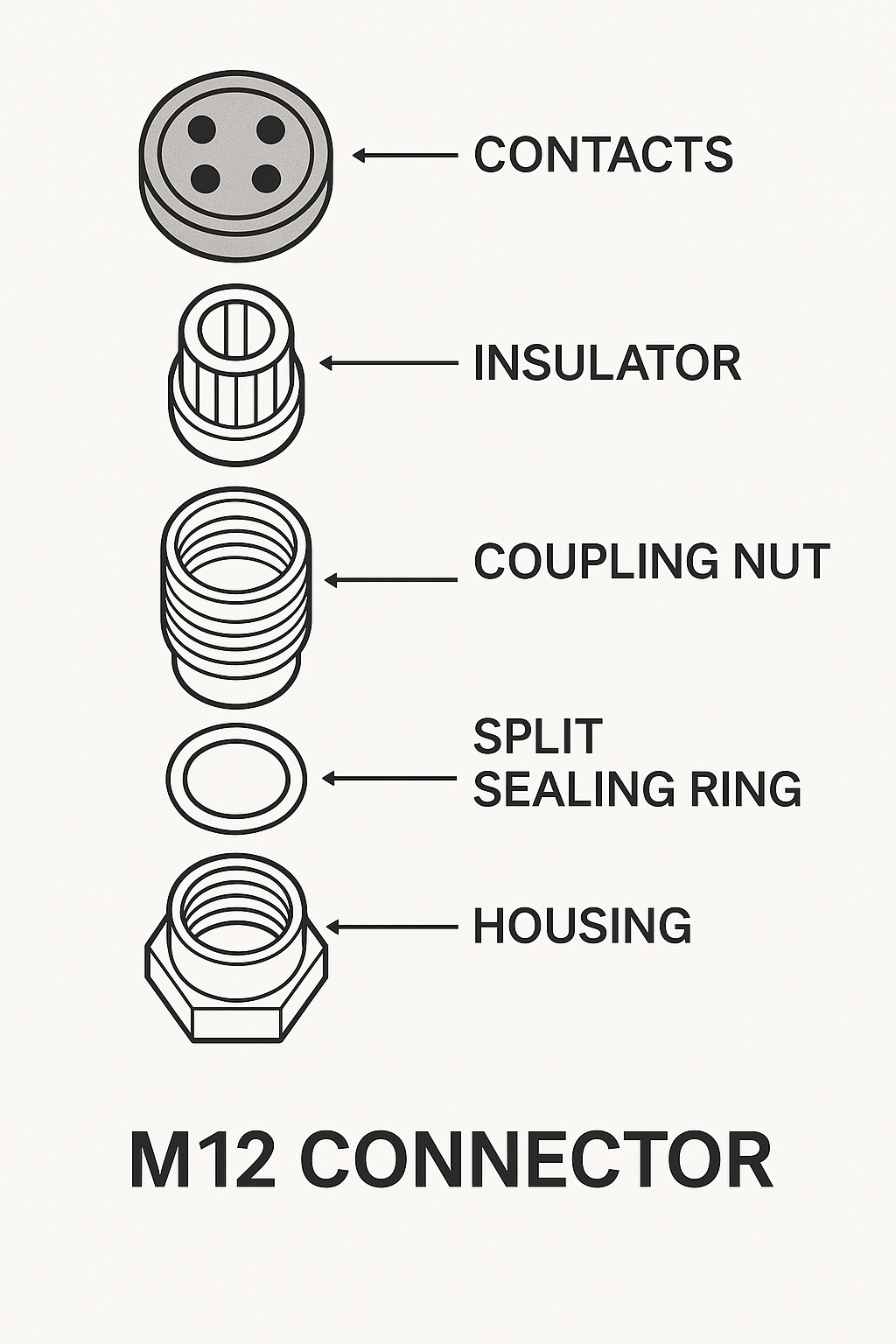

- Check for physical damage: cracked housings, broken latches, bent or recessed pins

- Look for contaminants: dirt, oil, or moisture on contacts

- Inspect sealing surfaces: ensure O-rings and locking systems are intact

Step 2: Verify Electrical Continuity

Use a multimeter to confirm uninterrupted current flow:

- Disconnect both ends of the cable

- Set the multimeter to continuity mode

- Probe corresponding pins at both ends

- Replace the cable if any pin fails the test

Connoder’s M12 cable assemblies are 100% factory-tested for continuity and resistance to help you avoid such failures from the outset.

Step 3: Wiggle Test for Intermittent Faults

Reconnect the cable to your device. Power the system on and gently move the connector and cable back and forth:

- A flickering signal or disconnection indicates internal wire breakage or poor contact

- This test is especially important in environments with frequent vibration

Step 4: Clean Connector Interfaces

If no issues are found, it may be a contact surface problem:

- Clean with 99% isopropyl alcohol

- Use compressed air to dry thoroughly

- Avoid aggressive solvents that can degrade insulation or seals

Step 5: Test Resistance and Insulation

Go beyond continuity with deeper diagnostics:

- Use insulation resistance testers for cables exposed to moisture

- Look for excessive resistance across pins that may indicate corrosion

- Match readings with connector specs from the datasheet

Step 6: Replace Faulty Connectors

If cleaning or testing reveals persistent problems:

- Replace the cable or connector entirely

- Ensure correct coding (A, B, D, or X) and pin orientation

- Connoder offers a full range of IP67/IP68-rated M12 connectors, compatible with all major systems

🛠️ Pro Tip from Connoder Engineers: Always torque M12 connectors to manufacturer-recommended levels to ensure long-term mechanical integrity and sealing.

When to Call Connoder

Sometimes, troubleshooting isn't enough — you need the right replacement, fast. That’s where Connoder’s support team steps in:

- Expert connector consultation

- Custom cable assembly services

- Global shipping and technical support

👉 Contact us directly for a solution tailored to your application

Bonus: Preventive Maintenance Checklist

- Inspect M12 connections quarterly

- Apply dielectric grease for harsh environments

- Use overmolded versions in high-vibration zones

- Keep documentation of testing and replacements