Why M16 Connectors Excel in Durability: Materials & Design

Why M16 Connectors Excel in Durability: Materials & Design

In demanding industrial environments, durability is more than just a feature—it’s a requirement. M16 connectors are celebrated for their rugged performance, and at Connoder, we take this durability even further through meticulous material selection and smart engineering.

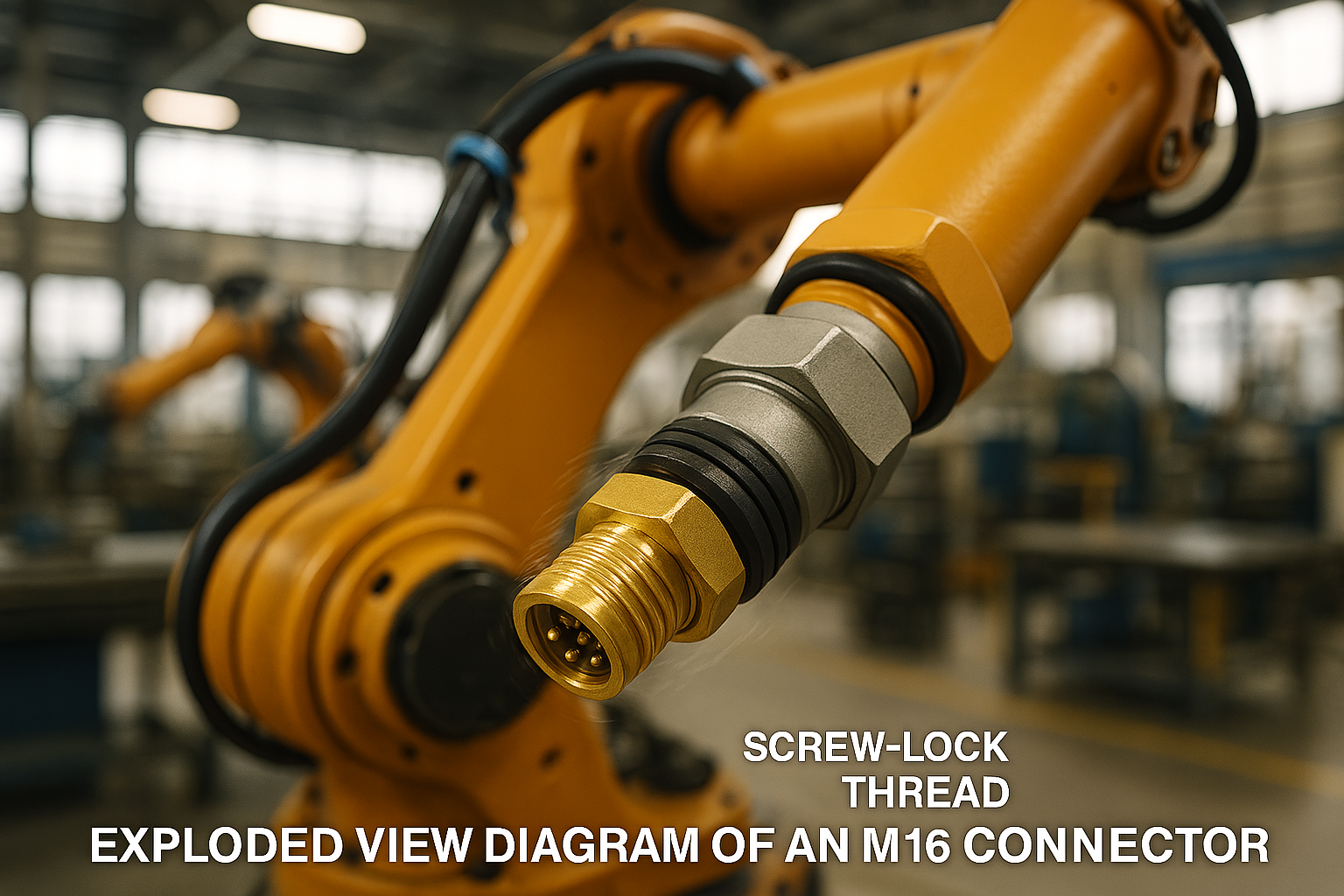

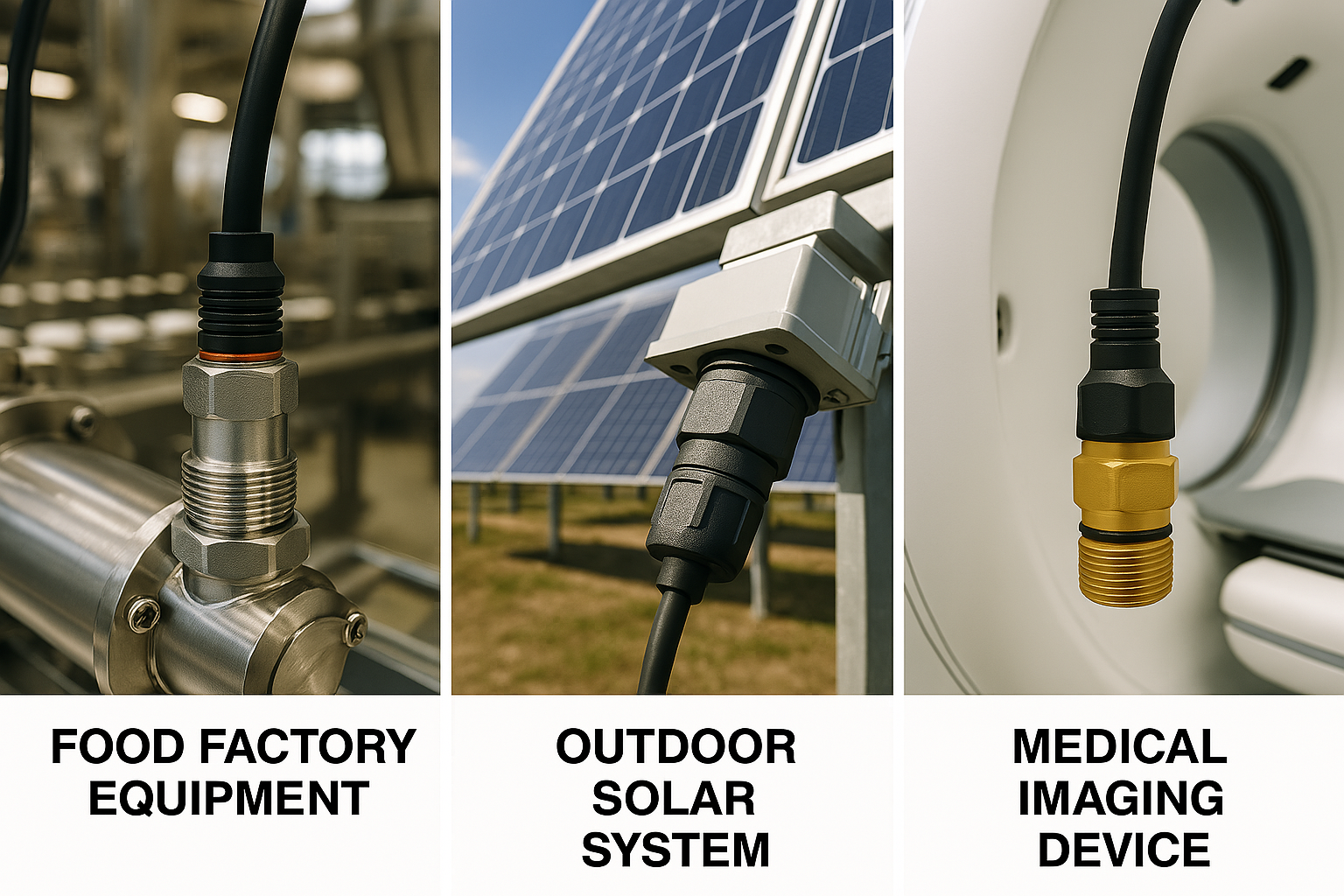

Built for Harsh Environments

M16 connectors are used across a wide range of applications—from smart automation to outdoor surveillance. These systems demand resistance to moisture, vibration, corrosion, and dust.

Durable by Design: Why Materials Matter

The foundation of connector longevity starts with materials. At Connoder, we use:

- Nickel-plated brass for mechanical strength and corrosion resistance

- Stainless steel for marine and chemical environments

- Engineering plastics like PBT for UV resistance and weight savings

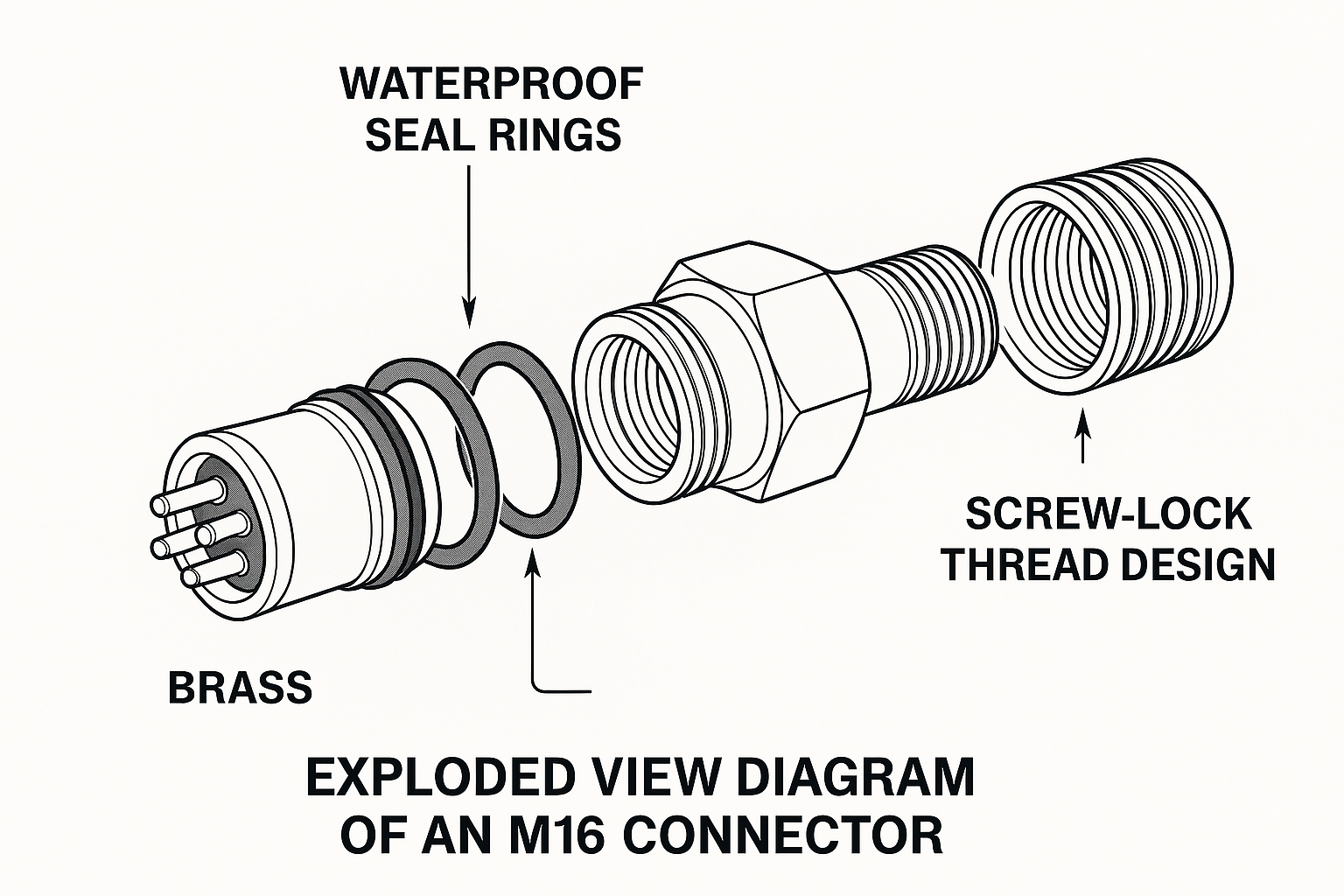

Engineering Excellence: IP67 & IP68 Sealing

Sealing performance is critical. Our M16 connectors feature:

- Secure screw-lock threads

- Multi-layer O-ring gaskets

- IP67 and IP68 ratings for dustproof and waterproof reliability

Endurance in Motion: Thermal and Vibration Resistance

Connoder's M16 connectors are tested for:

- More than 500 mating cycles

- Vibration resilience per IEC 60512

- Operating temperatures from -40°C to +105°C

Why Choose Connoder?

With over a decade of experience in connector engineering, Connoder provides:

- OEM customization

- ISO-certified production

- Fast delivery

- Technical guidance from selection to integration