How to Select M16 Connectors for Specific Applications

How to Select M16 Industrial Connectors for Specific Applications

Selecting the right M16 industrial connector is essential for ensuring reliable performance in industrial environments. Whether you’re working on factory automation, robotics, or outdoor applications, choosing the right connector reduces downtime, improves reliability, and guarantees compliance with international standards.

At Connoder, we specialize in designing and manufacturing premium M16 connectors. Our solutions are tested for durability and performance, making us your trusted partner for industrial connectivity. Learn more about us.

What Is an M16 Industrial Connector?

An M16 connector is a circular connector with a 16 mm thread, widely used in automation, robotics, and instrumentation. Key characteristics include:

- Pin Count: 2 to 24 pins for signal or power applications.

- Ingress Protection: Typically IP67 when mated, suitable for harsh conditions.

- Standards: Compliant with IEC 61076-2-106 for consistent quality.

High-quality Connoder M16 Industrial Connector with IP67 protection.

Key Factors When Selecting an M16 Connector

1. Environmental Conditions

If your application involves water, dust, or chemicals, select connectors rated at least IP67. Connoder offers ruggedized designs for outdoor and factory environments.

2. Electrical Requirements

Match voltage/current ratings to your system. For signal transmission, smaller pin counts (4–8 pins) work best; for combined power and signal, choose 12–24 pin options.

3. Mechanical Design

Decide between cable-mounted or panel-mounted connectors. All Connoder M16 connectors use screw-locking for vibration resistance.

4. Compliance & Safety

Ensure the connector meets IEC 61076-2-106, RoHS, and UL certifications for safety and reliability.

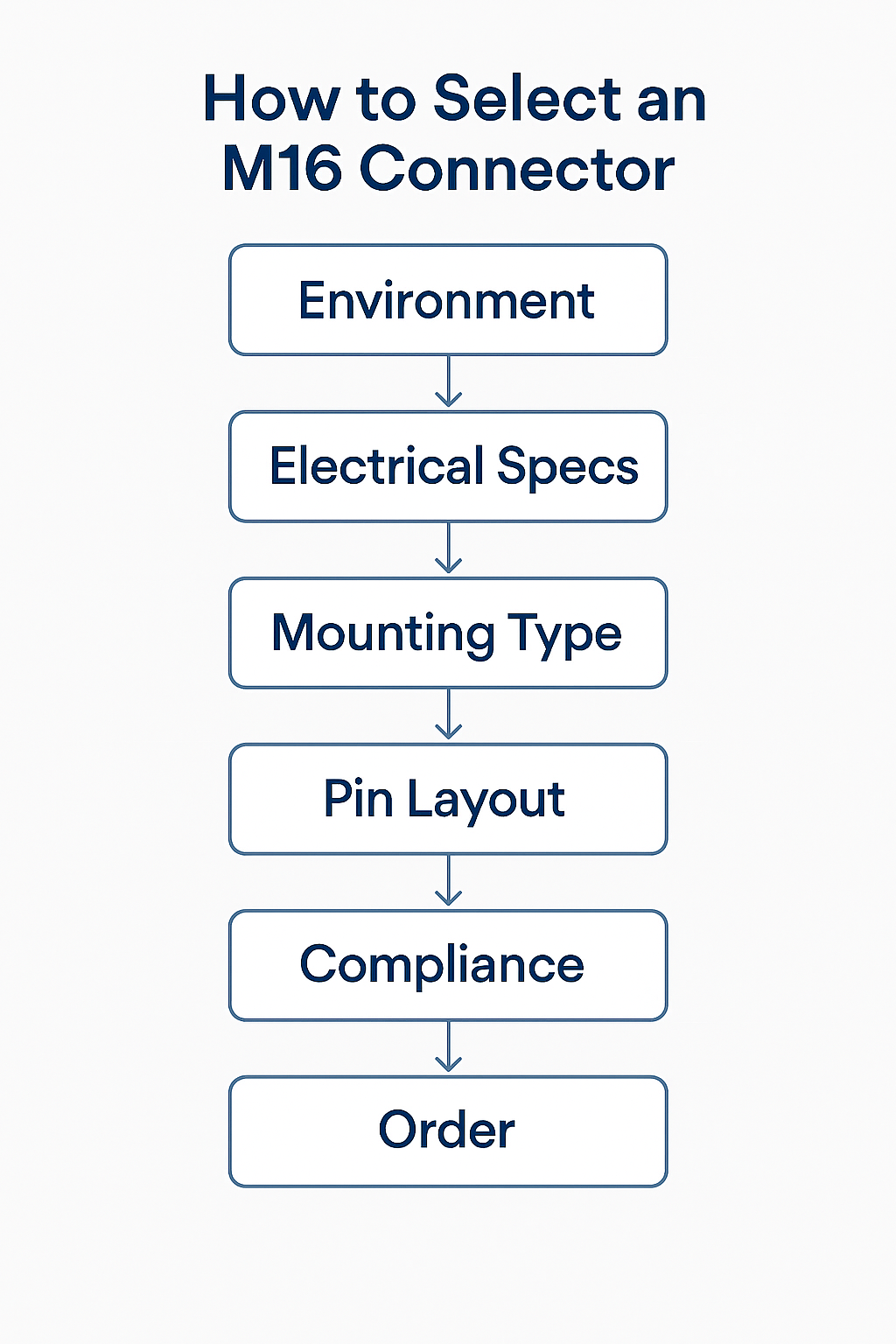

Step-by-Step Selection Guide

- Define environmental conditions (indoor/outdoor, waterproof).

- Determine electrical requirements (voltage/current, signal type).

- Select mounting type (panel or cable version).

- Choose pin configuration and termination method (solder, crimp, or screw).

- Confirm compliance and IP ratings.

- Contact Connoder experts for recommendations or custom designs.

Selection process for Connoder M16 industrial connectors.

Why Choose Connoder?

- Industrial Expertise: Years of experience producing high-performance connectors.

- Custom Solutions: Tailored pin layouts, cable assemblies, and overmolded solutions.

- Global Standards Compliance: IEC 61076-2-106 and international certifications.

Common Applications of M16 Connectors

- Factory Automation – Secure, IP-rated connectors for sensors and actuators.

- Robotics – High-flexibility cables for moving components.

- Outdoor Equipment – Weather-resistant connectors for harsh conditions.

Connoder M16 connectors used in automated machinery.

Ready to Select Your M16 Connector?

Contact Connoder today for expert guidance on selecting the right M16 industrial connector for your application. Whether you need standard products or fully customized solutions, our team is here to help.

FAQ

Q1: What IP ratings are available for Connoder M16 connectors?

Most of our M16 connectors offer IP67 protection when mated.

Q2: Can Connoder design custom connectors?

Yes! We provide custom designs, pin layouts, and special IP-rated solutions for unique requirements.

Q3: Which industries use M16 connectors?

Automation, robotics, renewable energy, medical devices, and outdoor telecom equipment.