Introduction: Why High-Reliability Connectors Matter in Aerospace

In aerospace environments, failure is not an option. Connectors are mission-critical components required to sustain power and signal integrity under extreme conditions — vibration, vacuum, radiation, and rapid thermal cycles. The M16 circular connector provides a compact, rugged form factor well suited to many aerospace uses where dependability is essential.

At Connoder, we combine years of connector design and manufacturing experience to deliver M16 circular connectors designed for harsh environments, backed by strict QA and customization capabilities.

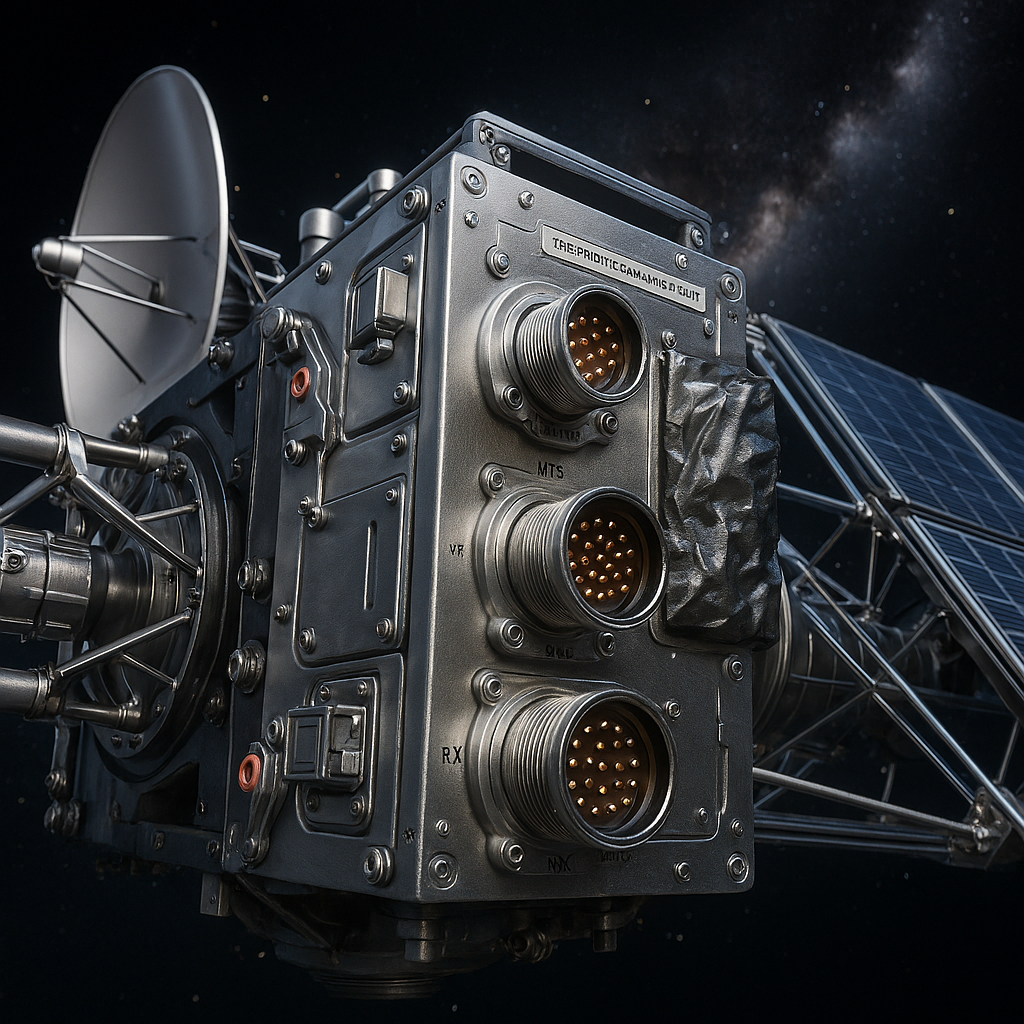

Rugged Connectors in Space Environments

Space and aerospace systems demand components that survive harsh physical and electromagnetic stresses. According to industry analyses, robust sealing (IP67/IP68), corrosion-resistant shells, and reliable mating cycles are core requirements. M16 connectors often meet these needs while offering moderate size and flexible pin configurations for telemetry, avionics, and ground support interfaces.

Telemetry and control systems on satellites

Launch vehicle avionics and payload interfaces

Ground support equipment exposed to weather and mechanical handling

Powering Space Exploration: Proven Cases

Long-running space missions show that connector qualification and conservative design greatly reduce mission risk. High-density pin layouts, effective EMI shielding, and vibration-resistant contacts are common traits of successful aerospace connector deployments.

Hermetic Connectors: Crucial for Space Applications

Hermetic sealing prevents ingress of gas, moisture, and particulates — a requirement for many space payloads and high-altitude systems. Glass-to-metal seals, controlled leak-rate testing, and compatible insulator materials are typical hermetic practices used in aerospace connector design.

Connoder offers hermetic M16 variants engineered for leak-tight performance and tested across thermal and vibration profiles relevant to aerospace projects.

Why Choose Connoder for Aerospace-Grade M16 Connectors

Expertise: Over a decade of dedicated focus on circular connectors and ongoing R&D to adapt designs for harsh environments.

Authoritativeness: Product design and qualification align with aerospace design philosophies used by leading industry suppliers.

Trustworthiness: Rigorous testing (vibration, thermal cycling, leak rate, EMI) and traceable QA processes ensure consistent performance.

Customization: Tailored pinouts, shell materials, sealing options, over-molded cable assemblies and harness solutions to meet your specification.

Learn more about our company and capabilities on the Connoder About Us page.

Key Aerospace Applications for M16 Circular Connectors

Satellite Telemetry

Shielded M16 connectors support reliable data links for satellite subsystems and payload instruments.

Avionics Modules

Compact, rugged, and serviceable connectors for flight control and cockpit electronics.

Ground Support Equipment

Weather-resistant connections used repeatedly during launch preparation and testing.

Propulsion & Sensors

Robust connections for high-vibration and high-temperature sensor locations.

Design & Selection Guidelines

Specify the environmental profile early (temperature, vibration, vacuum, radiation).

Choose appropriate sealing — hermetic or high-IP sealing depending on mission needs.

Verify mechanical ruggedness and mating cycle requirements.

Pay attention to materials and plating for corrosion resistance and conductivity.

Test for EMI/EMC and signal integrity under real assemblies and harness routing.

Maintain documentation and traceability for all components and batches.

Example — Connoder M16 Hermetic Connector

Example — Connoder M16 Hermetic Connector

An M16 circular connector variant with glass-to-metal sealing, IP68 rating, metal shell and tested operational range of −40 °C to +125 °C. stable contact resistance after 500 mating cycles, and verified EMI shielding performance.

Aerospace projects require components proven to survive the harshest conditions. Properly specified and manufactured M16 circular connectors deliver a reliable balance of size, sealing, and electrical performance — and Connoder’s product line is engineered to meet these exacting demands.

If you are designing for satellite systems, UAVs, avionics, or ground support, contact Connoder to discuss custom M16 solutions, request samples, or receive qualification data.

What kind of high-reliability connector is used in aircraft engine control systems, and how does it ensure stable operation?

A typical case is the use of titanium alloy shell + gold-plated pin connectors (e.g., TE Connectivity’s Aerospace series) in aircraft engine ECS (Engine Control Systems). The titanium alloy shell resists high temperatures (up to 280°C) and vibration (10-2000Hz, 50G acceleration) from the engine; the gold-plated pins have a contact resistance of <10mΩ, ensuring uninterrupted transmission of fuel injection and speed control signals. In a Boeing 787 engine project, this type of connector maintained zero failure for 8000+ flight hours, fully meeting aerospace safety standards.

How do high-reliability connectors solve the problem of "moisture and pressure difference" in spacecraft cabin connections?

A classic case is the hermetically sealed micro-D connectors (e.g., Amphenol’s Space Micro-D series) used in the International Space Station (ISS) cabin. These connectors adopt a "glass-metal sealing" process – the interface is sealed with high-temperature resistant glass, achieving IP69K-level waterproof and airtight performance. When the ISS transitions between low-Earth orbit (vacuum) and atmospheric re-entry (pressure difference of 101kPa), the connectors prevent moisture intrusion and gas leakage. In 10+ years of ISS operation, this connector case has supported stable data transmission between life support systems and control modules.

Which high-reliability connector is suitable for satellite solar panel connections, and how does it resist space radiation?

A representative case is the polyimide-insulated + nickel-plated copper connector (e.g., Smiths Interconnect’s Satellite series) used in satellite solar arrays. The polyimide insulation layer can withstand 100kGy of space radiation (equivalent to 10 years of orbital radiation exposure) without aging; the nickel-plated copper pins have strong anti-oxidation properties, avoiding contact failure caused by cosmic particle erosion. In China’s Tianwen-1 Mars rover solar panel project, this connector maintained 99.9% power transmission efficiency during the 7-month interplanetary flight, ensuring the rover’s energy supply.

How do high-reliability connectors ensure "anti-misplug and quick maintenance" in aircraft avionics bays?

A practical case is the coding-type rectangular connectors (e.g., Harting’s Aerospace Han® series) used in Airbus A350 avionics bays. Each connector has a unique mechanical coding (e.g., A/B/C/D coding slots) – only matching codes can be plugged in, avoiding misconnection of navigation and communication signals. Additionally, the connector adopts a "quick-lock" structure: maintenance personnel can complete disassembly and reinstallation in 30 seconds (without tools), reducing aircraft downtime. This case has been promoted in 500+ A350 aircraft, significantly improving maintenance efficiency.

M16 6 Pin Circular Connector A-Code Interface, Waterproof Connector Receptacle Cable, Straight, Front-Locking, Unshielded

M16 6 Pin Circular Connector assemblies are ideal for demanding industrial applications such as industrial automation and aerospace, marine, and telecom systems.

M16 6 Pin Circular Connector are ideal for demanding industrial applications such as industrial automation and aerospace, marine, and telecom systems. M16 Circular Connector are available in quick-lock wiring assembly types with IP67 protection and a vibration-resistant screw design.

M16 6 Pin Circular Connector are ideal for demanding industrial applications such as industrial automation and aerospace, marine, and telecom systems. M16 Sensor connector are available in quick-lock wiring assembly types with IP67 protection and a vibration-resistant screw design.