Five major innovation directions for the M16 circular connector industry in the next five years

Introduction

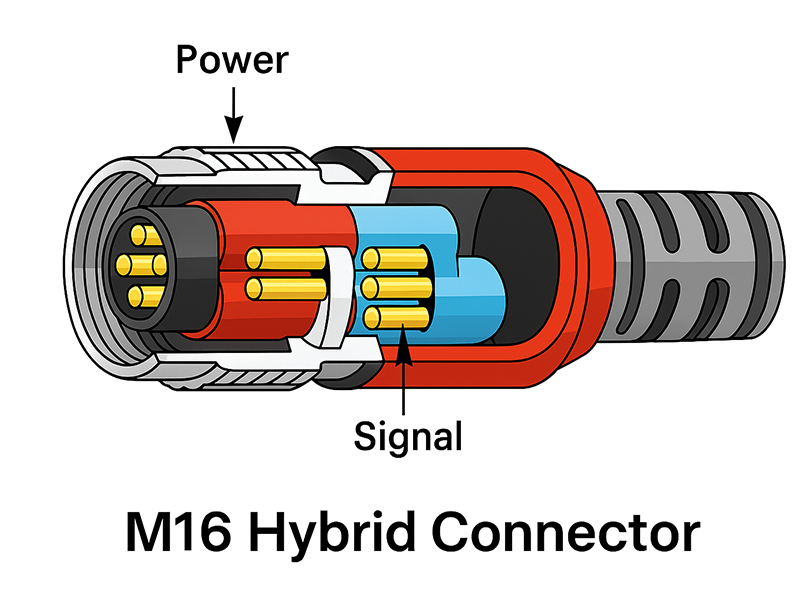

The M16 circular connector has been a cornerstone in industrial automation, smart manufacturing, and outdoor electronics for decades. As global technology rapidly evolves, so too must the M16 connector adapt to new performance demands. Recent industry analyses indicate that innovation in connector technology will accelerate between 2025 and 2030.

As a trusted connector manufacturer, Connoder is at the forefront of these developments. With decades of engineering expertise and a commitment to reliability, we are not only keeping pace with industry changes but driving them — especially in the field of M16 circular connectors.

1. Advanced Environmental Protection (IP68 and Beyond)

2. High-Density Hybrid Integration

3. Smart & Sensor-Enabled Connectors

4. New Materials and Manufacturing Processes

5. Contactless & Inductive Coupling