High-End vs. Standard Connectors: Why the Price for an M16 Circular Connector Differs

Introduction

When sourcing circular connectors—especially the M16 series—you may notice significant differences in pricing among suppliers. At first glance, similar-looking connectors can vary widely in cost. So, what drives the M16 circular connector price?

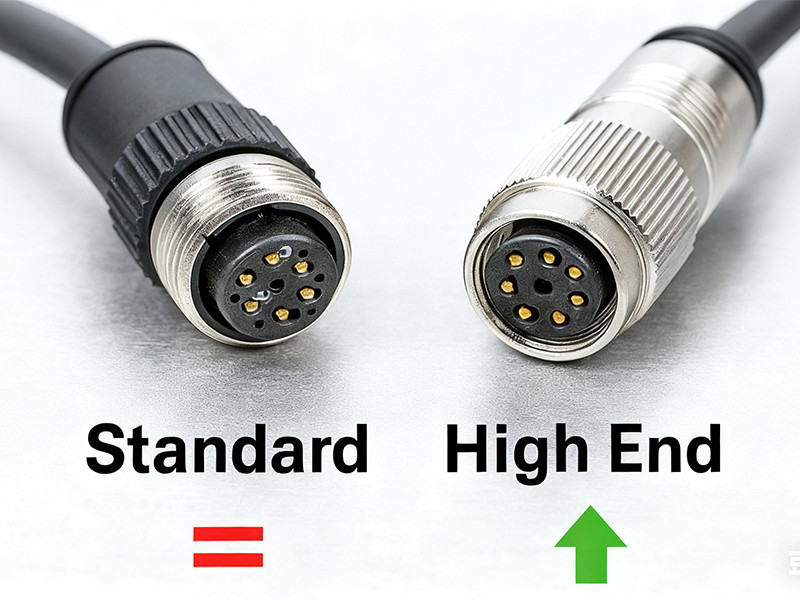

1. High-End vs. Standard Connectors — What’s the Difference?

2. The Key Factors That Influence M16 Circular Connector Price

3. Price Comparison: Standard vs. High-End M16 Connectors

| Type | Typical Price (USD) | Material | IP Rating | Applications |

| Standard M16 | $8 – $15 | Plated Brass / Plastic | IP67 | General industrial use, sensors |

| High-End M16 | $25 – $45+ | Nickel-Plated Brass / Stainless Steel | IP68+ | Robotics, marine, EV systems |

4. The Long-Term Value of High-End M16 Connectors

5. Why Choose Connoder