How to choose the right circular connector for harsh environments

Introduction

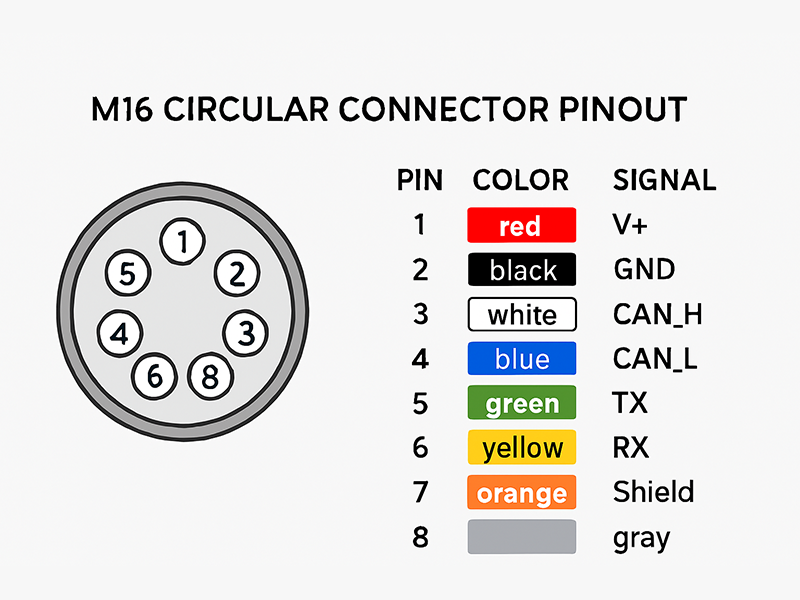

In industrial automation, robotics, outdoor sensors and other demanding applications, selecting the right circular connector is critical for system reliability and performance. Among connector families, M16 circular connectors stand out for their compact size, multi-pin capability, and rugged design.

Why M16 Circular Connectors Are Ideal for Harsh Environments

How to Choose the Right Circular Connector for Harsh Environments

Integration & Installation Best Practices