Selection of Precision Connectors in Medical Imaging Equipment

Introduction

Medical imaging systems demand highly reliable, compact and precisely engineered interconnects. Among these, the M16 circular connector family stands out as an excellent option when space is tight, performance demands are high, and environments are challenging. This article explores how M16 circular connectors are applied in imaging equipment, outlines selection criteria, and highlights how Connoder supports OEMs in this field.

Why M16 Circular Connectors Matter in Imaging Equipment

Typical Imaging Applications for M16 Circular Connectors

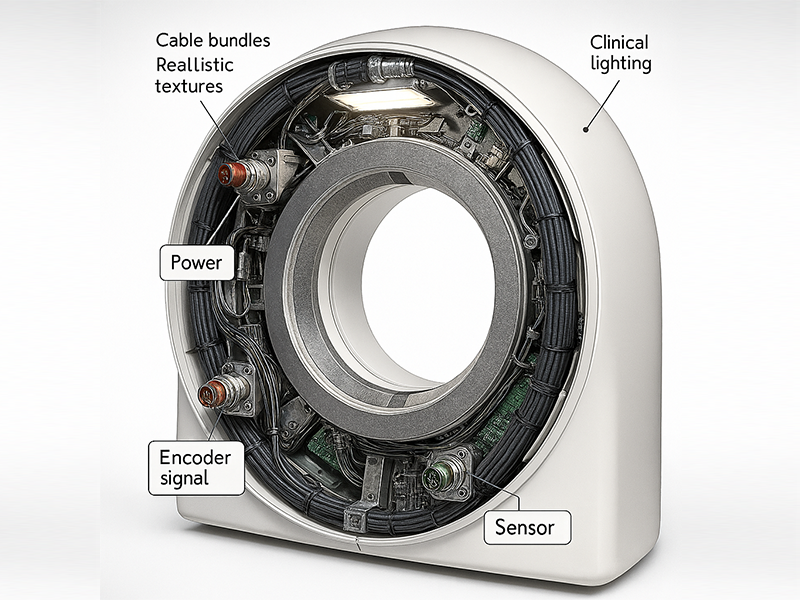

1. Gantry and Module Wiring in CT / X-ray Systems

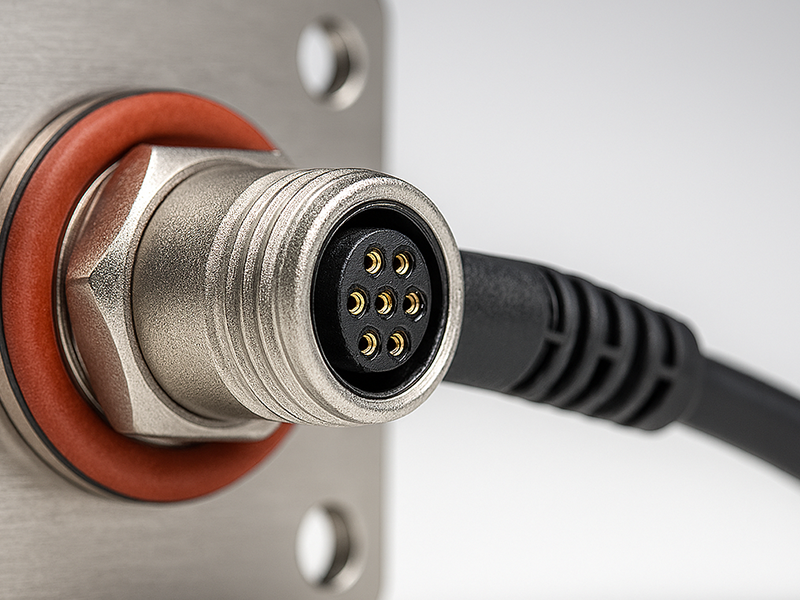

Inside a CT or X-ray gantry, space is constrained, and wiring must withstand vibration, rotation, temperature shifts, and electromagnetic noise. M16 circular connectors offer secure locking, high signal integrity, and IP-rated sealing for this purpose.

2. Ultrasound Console and Probe Interfaces

Portable ultrasound systems require durable connectors between probes and consoles. High-cycle M16 connectors provide consistent signal performance even under frequent connection and disconnection.

3. MRI-Compatible Non-Magnetic Connectors

MRI environments demand non-magnetic, shielded, and low-EMI connectors. Connoder’s M16 product line includes non-magnetic housing options designed for safety and signal clarity.

4. Mobile Imaging and Point-of-Care Systems

Mobile and portable imaging devices require rugged yet lightweight connectors. Sealed M16 designs protect against cleaning agents and ensure durability in clinical environments.

5. Display, Control, and Camera Subsystems

Compact circular connectors like M16 simplify wiring for control panels, sensors, and imaging cameras — providing modularity and ease of servicing.

Selecting the Right M16 Connector for Imaging Applications

| Category | Key Considerations |

| Electrical / Signal Integrity | Define voltage/current, shielding, data rate, impedance. Use shielded contacts for low-noise imaging systems. |

| Mechanical / Environmental | Required IP rating (IP67/IP68), mating cycles, vibration and rotation resistance. |

| Imaging Constraints | Non-magnetic materials for MRI, EMI protection for CT and digital X-ray systems. |

Sterilisation & Hygiene | Resistance to cleaning agents, moisture, and disinfectants. |

Supplier Credentials | Choose ISO-certified suppliers with medical experience — such as Connoder. |

Installation & Maintenance Best Practices

Why Choose Connoder for Medical Imaging Connectors