The impact of the Industry 4.0 era on the M16 circular connector industry

Introduction

As the Industry 4.0 era transforms modern manufacturing, connectivity is at the heart of every smart factory. From IIoT sensors and robotics to AI-driven control systems, robust interconnection is essential. At the core of this shift lies the M16 Circular Connector standards, defined by IEC 61076-2-106, which ensure that connectors deliver the reliability, durability, and performance demanded by next-generation industrial automation. In this article, we’ll explore how Industry 4.0 impacts the M16 circular connector market, what the standards mean for engineers and buyers, and how Connoder provides compliant, high-performance solutions for smart manufacturing.

CONNODER provides engineered interconnect solutions and custom M16 connector assemblies for demanding environments.

Why Industry 4.0 is Changing Connector Requirements

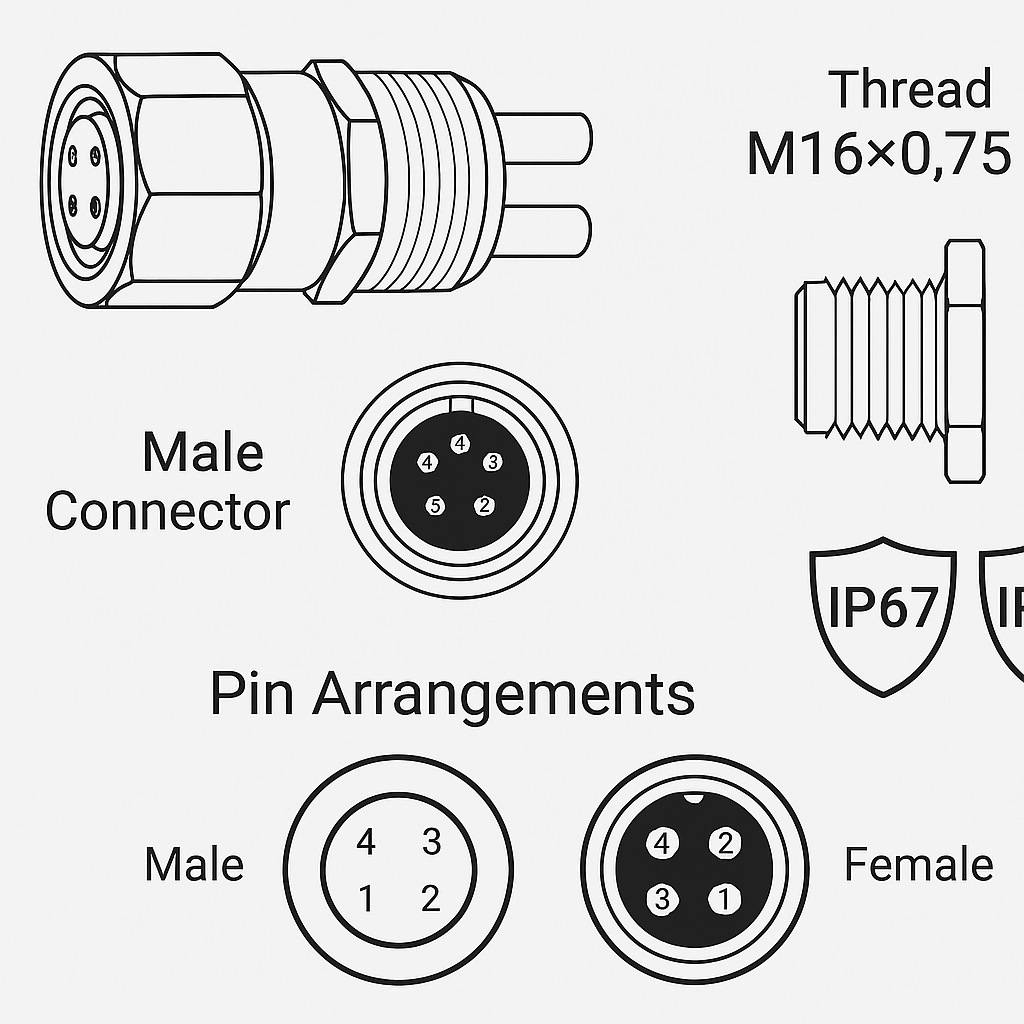

M16 Circular Connector Standards Explained

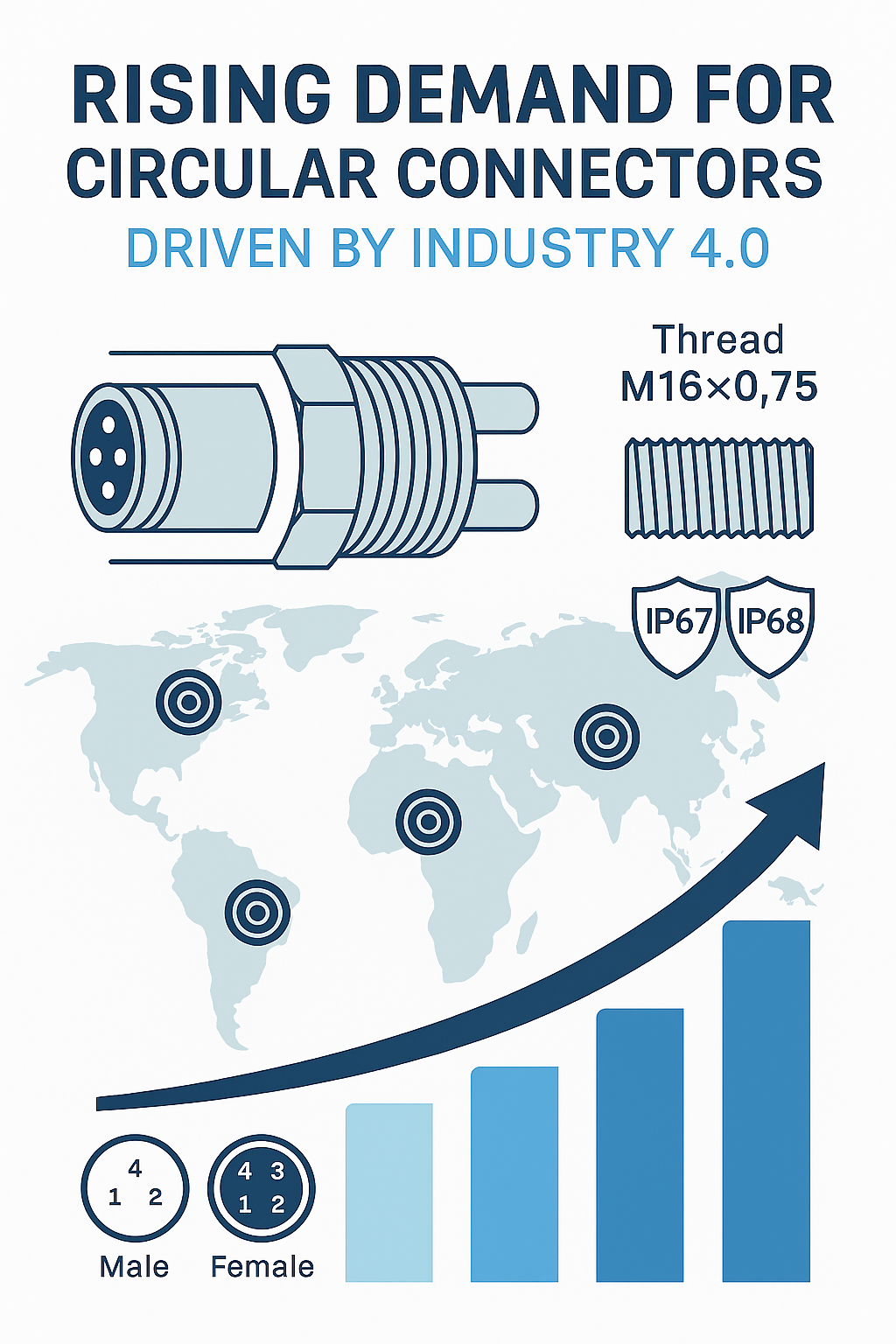

Growth Driven by Industry 4.0

Connoder’s Role in the Industry 4.0 Era

Practical Applications of M16 Circular Connectors