The ten advantages of the M16 circular connector

Introduction

When engineers and system designers search for “M16 circular connector datasheet”, they’re seeking precise technical data — but also compelling reasons to select M16 over other connector types. This article outlines the ten key benefits of M16 circular connectors, grounded in industry standards and real-world datasheet specifications. We also introduce Connoder — a trusted brand in the connector industry — and show how our M16 product line embodies these advantages.

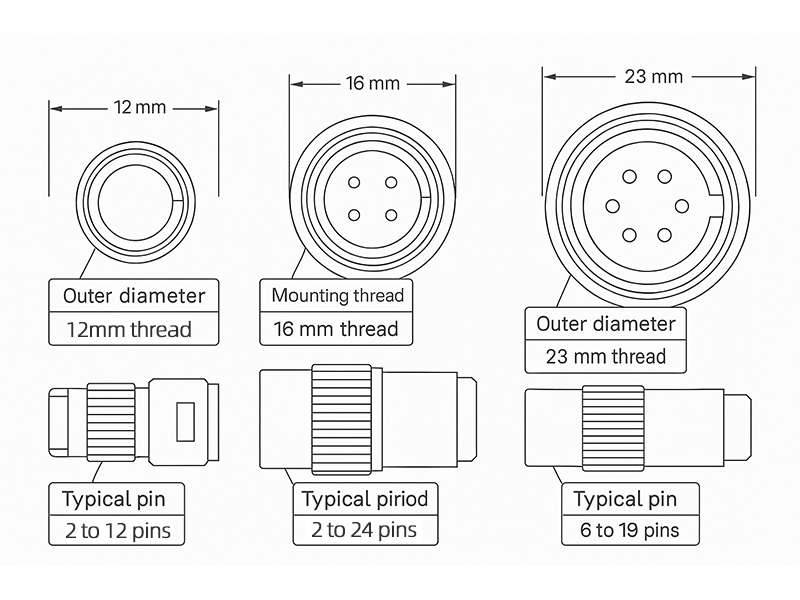

1. Compact Design with High Contact Density

2. Robust Environmental Sealing (IP67 / IP68)

3. Long Mechanical Life & High Mating Cycles

4. Superior Electrical Performance

5. Flexible Pin Layouts & Keying

6. EMI Shielding & Noise Management

7. Corrosion Resistance & Material Quality

8. Field-Installable / Ease of Termination

9. Cost-Effectiveness in Industrial Volume

10. Proven Adoption & Interoperability