The top ten most anticipated technological breakthroughs in M16 circular connectors in 2025

Introduction

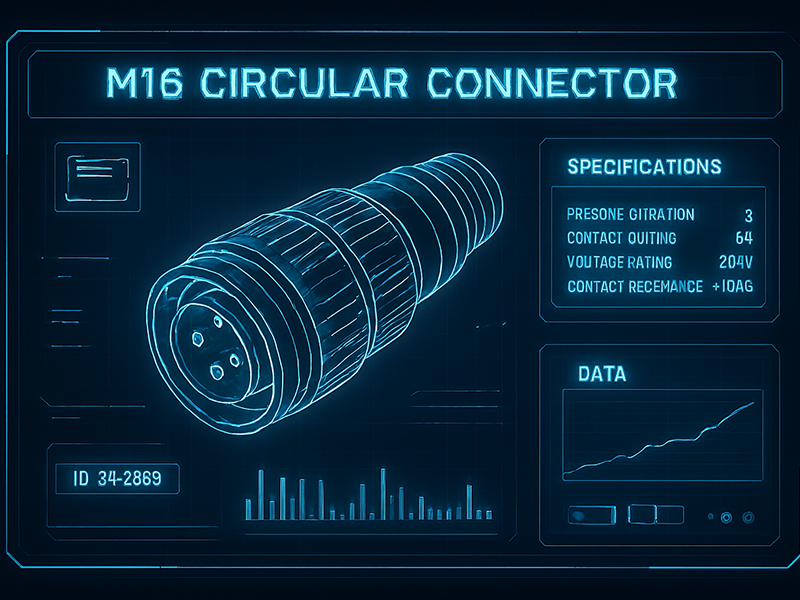

The M16 circular connector has long been a cornerstone in industrial automation, robotics, and sensor systems — offering a robust, compact, and reliable solution for power and signal transmission. As we move into 2025, the connector industry is witnessing remarkable innovations aimed at improving durability, data transmission efficiency, and environmental resistance. In this article, Connoder — a leading global manufacturer specializing in M-series circular connectors — explores the ten most anticipated technological breakthroughs shaping the next generation of M16 circular connectors, based on insights from the latest market reports and product trends.

1. Smart Data Integration in M16 Circular Connector Data Sheets

2. Advanced Waterproofing & IP69K Protection

3. High-Speed Data Transmission Capability

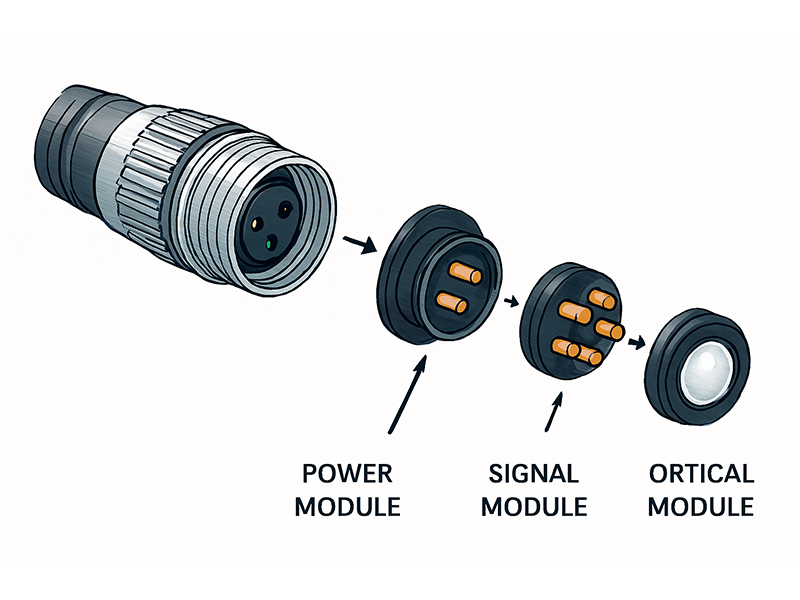

4. Modular Hybrid Design

5. Sustainable & Eco-Friendly Materials

6. Miniaturization for Compact Systems

7. Enhanced Corrosion Resistance for Marine & Offshore Use