How do I choose the right connector for my industrial equipment (e.g., on-site sensors, control cabinets)?

Focus on three core factors: first, environmental adaptability – select connectors with IP67/IP68 rating if the site has dust, moisture, or vibration (e.g., M12 circular connectors for sensors); second, electrical performance – match current/voltage requirements (e.g., high-current scenarios need silver-plated connectors, while high-frequency signal transmission needs gold-plated ones); third, installation space – choose miniaturized or high-density connectors (e.g., board-to-board connectors) if the equipment interior is compact. Avoid over-specifying (e.g., using aerospace-grade connectors for ordinary industrial control) to balance performance and cost.

My existing connector is from Brand A, can I replace it with a compatible one from Brand B to save cost?

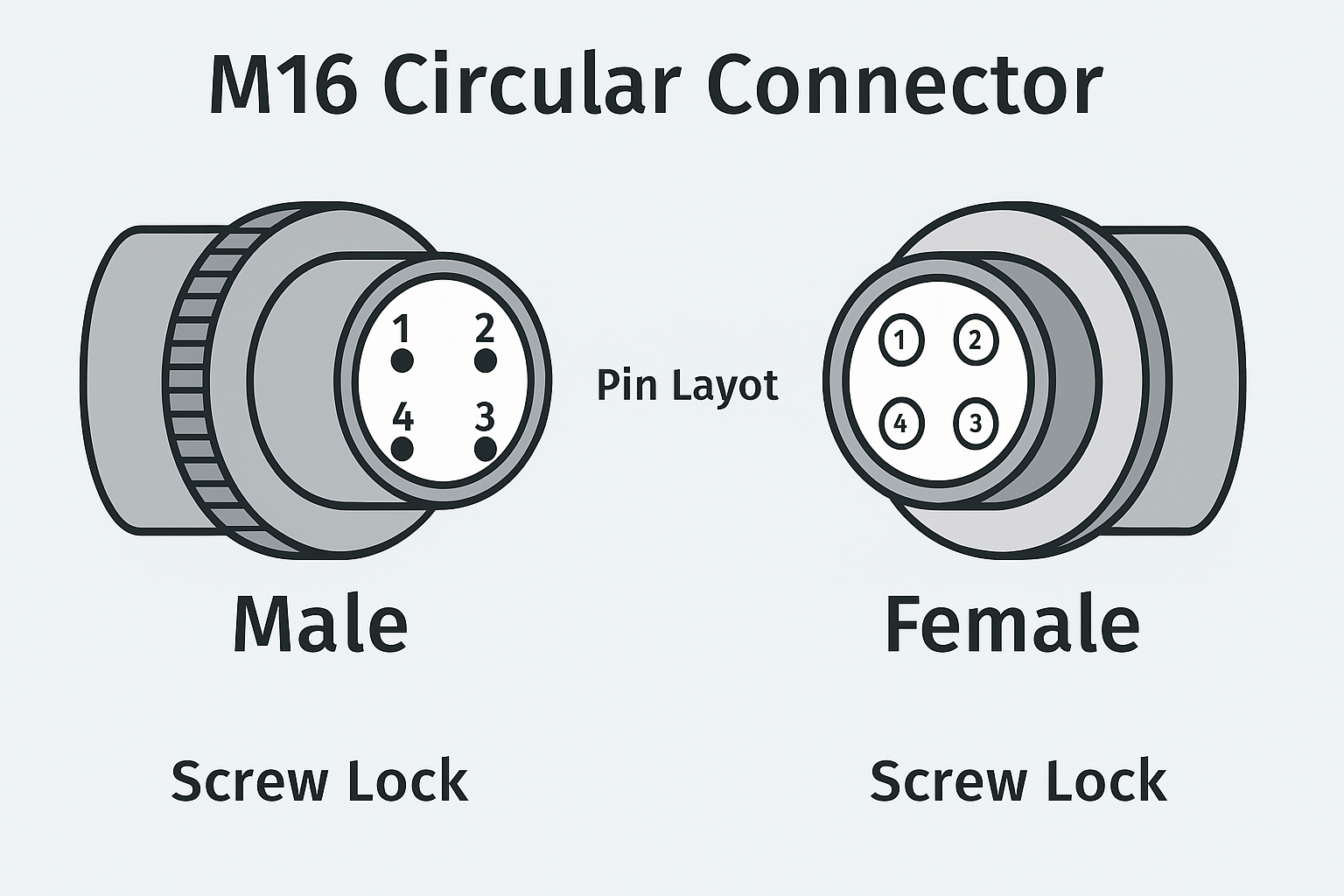

It depends on "mechanical and electrical compatibility": first, check physical dimensions (e.g., interface diameter, pin spacing, fastening structure) – ensure they are consistent with Brand A’s specifications (e.g., M16 connectors must have the same thread size); second, verify electrical parameters (e.g., contact resistance, insulation resistance, rated current) – they should meet or exceed the original standard; third, confirm coding compatibility (for anti-misplug connectors) – if Brand A uses A-coding, Brand B’s replacement must also be A-coding. It’s recommended to test 2-3 samples first (e.g., conduct continuity and vibration tests) before batch replacement.

Why does my connector fail after only a few months of use, even though it’s supposed to have a 5-year service life?

Common causes include: ① improper installation (e.g., excessive torque leading to shell cracking, or insufficient insertion force causing loose contact); ② environmental damage (e.g., unprotected use in high-humidity environments leading to terminal corrosion, or dust accumulation blocking the interface); ③ overload operation (e.g., using a 5A connector for 10A current, causing overheating and 镀层 melting). To extend life, follow the manual for installation (control torque/insertion force), add protective measures (e.g., dust caps for unused connectors), and avoid exceeding rated parameters.

How do I troubleshoot "intermittent contact" issues with my connector (e.g., the device occasionally powers off or signals drop)?

Follow this step-by-step process: ① visual inspection – check if the connector shell is cracked, pins are bent, or there’s rust/oxidation on the contacts; ② mechanical check – gently wiggle the connector and wire harness – if the issue recurs, it may be loose fastening or poor crimping; ③ electrical testing – use a multimeter to measure contact resistance (normal value: <50mΩ) – if it’s too high, clean the contacts with alcohol (avoid abrasive materials) or replace the connector; ④ environmental check – if used outdoors, verify if the seal is damaged (e.g., O-ring falling off) and replace the seal if needed.