The miniaturization and high-density application of M16 connectors

M16 Circular Connector Applications: High-Density Innovation in a Compact Format

Why M16 Circular Connectors Are Widely Used

M16 circular connectors are essential components in modern electronics due to their versatile design, robust performance, and adaptability across multiple industries. From industrial automation to medical devices, automotive, and aerospace, these connectors provide compact, secure, and high-performance electrical connections.

Connoder has been at the forefront of developing M16 connectors with tailored specifications that meet the demanding needs of compact systems. Learn more about Connoder →

The Miniaturization Trend: What It Means for M16 Connectors

With the rise of wearable devices, smart sensors, and IoT platforms, space-saving designs are critical. M16 connectors are evolving to support miniaturization without compromising reliability.

- Space constraints in consumer and industrial electronics

- High pin density for mixed signal and power transmission

- Lightweight & low-profile designs for portable devices

- Demand for modular systems in green energy and 5G applications

Referenced Insight: AmissionTech highlights the importance of M16 connectors in small-scale and hybrid environments.

High-Density M16 Solutions in Real-World Applications

- Industrial Automation: Powering sensor-actuator loops, fieldbus networks, servo motors in tight control cabinets.

- Automotive & EV Systems: Weatherproof, vibration-resistant M16s in BMS and vehicle electronics.

- Medical Equipment: Used in patient monitors, imaging, and diagnostic instruments with strict space limits.

- 5G and Smart Infrastructure: Supports high-speed data in harsh environments, with IP67 protection and EMI shielding.

Connoder’s Advantage: Custom M16 connectors with hybrid pin layouts, IP68 sealing, and precision coupling mechanisms for rugged and compact devices.

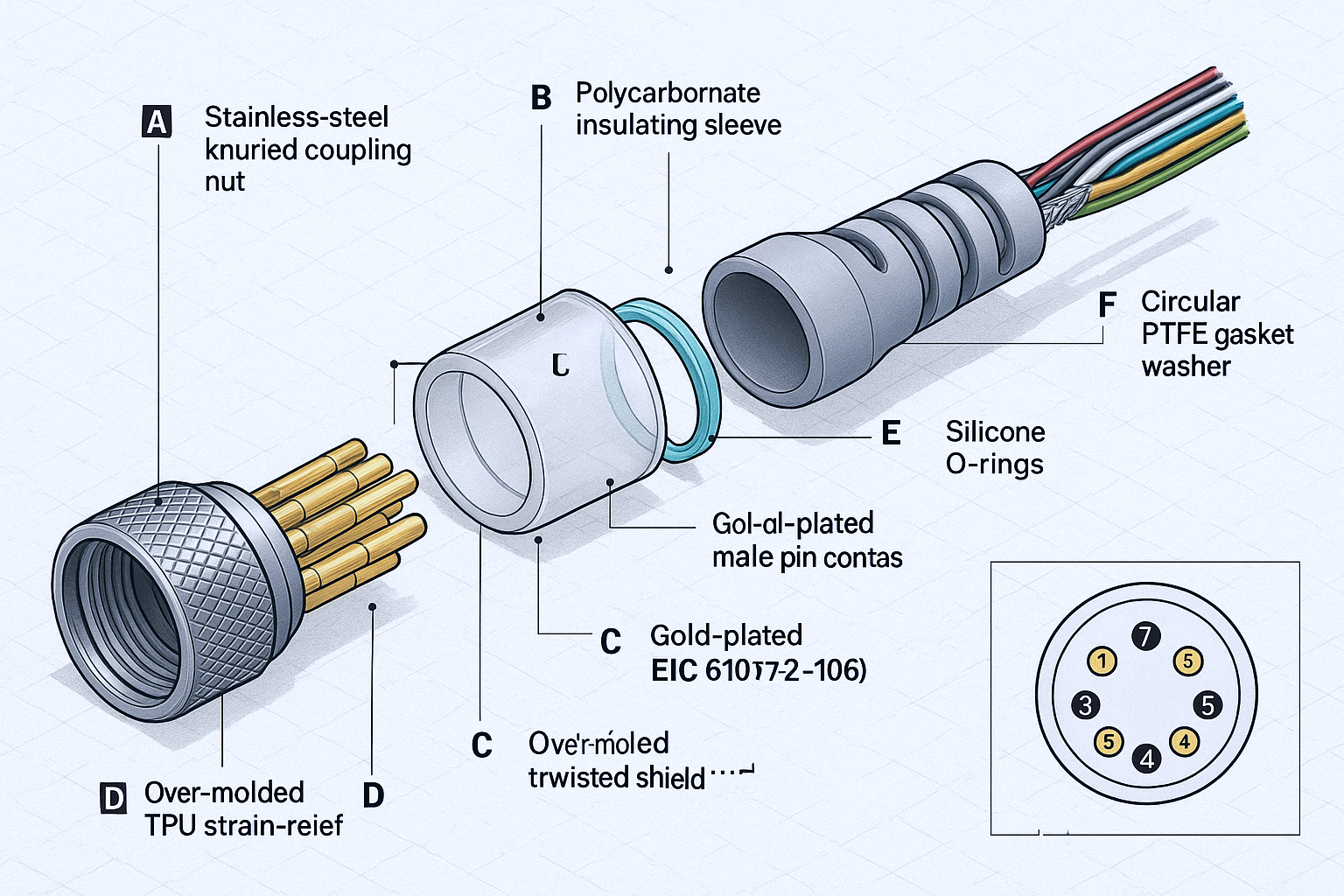

Connoder's compact, high-pin-count M16 circular connector installed on a precision PCB

Technical Advantages of Miniaturized M16 Connectors

| Feature | Benefit |

|---|---|

| High Pin Density (Up to 24) | Supports data, signal, and power in a single compact connector |

| IP67/IP68 Protection | Ideal for outdoor, industrial, and medical environments |

| Modular Design | Customizable pin layouts to match device-specific requirements |

| Quick/Thread Lock Systems | Secure and vibration-resistant connections |

| Reduced Dimensions | Saves up to 40% space vs legacy connectors |

Connoder’s Expertise in M16 Miniaturization

With over 15 years in precision connector manufacturing, Connoder provides:

- ISO 9001 & ISO 14001 certified production

- ODM/OEM support for custom pin layouts

- Fast prototyping & volume production

- Global logistics and engineering services

Learn more about our company →

Innovation Spotlight – Case Study

Project: Wearable Medical Sensor Connector

- Challenge: Fit a 12-pin M16 connector in a 15mm space

- Solution: Hybrid layout with 2 power + 10 signal pins, over-molded and IP67 sealed

- Result: 35% footprint reduction, 3x longer device life

Miniaturized M16 connector used in a compact medical sensor by Connoder

How to Choose the Right M16 Connector

- Total signal vs. power pin requirements

- Environmental resistance: water, dust, vibration

- Mating cycles and lifespan

- Mounting style: panel, PCB, or cable-end

- Compliance: UL, RoHS, REACH

Need help? Connoder’s engineers will help you configure the optimal solution.

Contact Us for Custom M16 Solutions

Looking for a compact, rugged, and high-performance connector?

- Free consultation and sample options

- Direct support from experienced engineers

- Fast prototype and mass production service